by Hanshin-Imports | Feb 27, 2024

| APPLICATION |

DURATION(°) |

MAX CAM LIFT(mm) |

IN/EX |

P/N |

CHF |

| エンジン |

車種 |

IN |

EX |

IN |

EX |

| BP-ZE |

NA8C |

252 |

256 |

9.20 |

9.50 |

IN & EX Set |

143053 |

799.-CHF |

| 252 |

9.20 |

IN |

1495252092 |

405.-CHF |

| 256 |

9.50 |

EX |

1496256095 |

※PRESET VALVE TIMING

※STOCK VALVE SPRING COMPATIBLE

FEATURE / SPEC

■ Designed to optimise the true performance potential of the NA engine throughout the entire RPM range.

*Instant Response: Quicker response from the engine with the touch of the throttle.

*Flat Mid Range: Stable smooth mid range.

*Rev Harder: Will rev much faster & rev to redline quicker than ever before.

*Can be fitted as normal on stock head.

*You will see performance gains even on the stock ECU.

■ SPEC

| Duration |

Max Cam lift (mm) |

IN/EX |

Max Valve lift (mm) |

Cold Valve Clearance

(mm)[±0.01] |

Valve Timing Centerline

(Deg) |

Base circle |

Note |

| 252 |

9.20 |

IN |

9.20 |

– |

110 |

33.6 |

Lash type |

| 256 |

9.50 |

EX |

9.50 |

34.2 |

by Hanshin-Imports | Dec 19, 2023

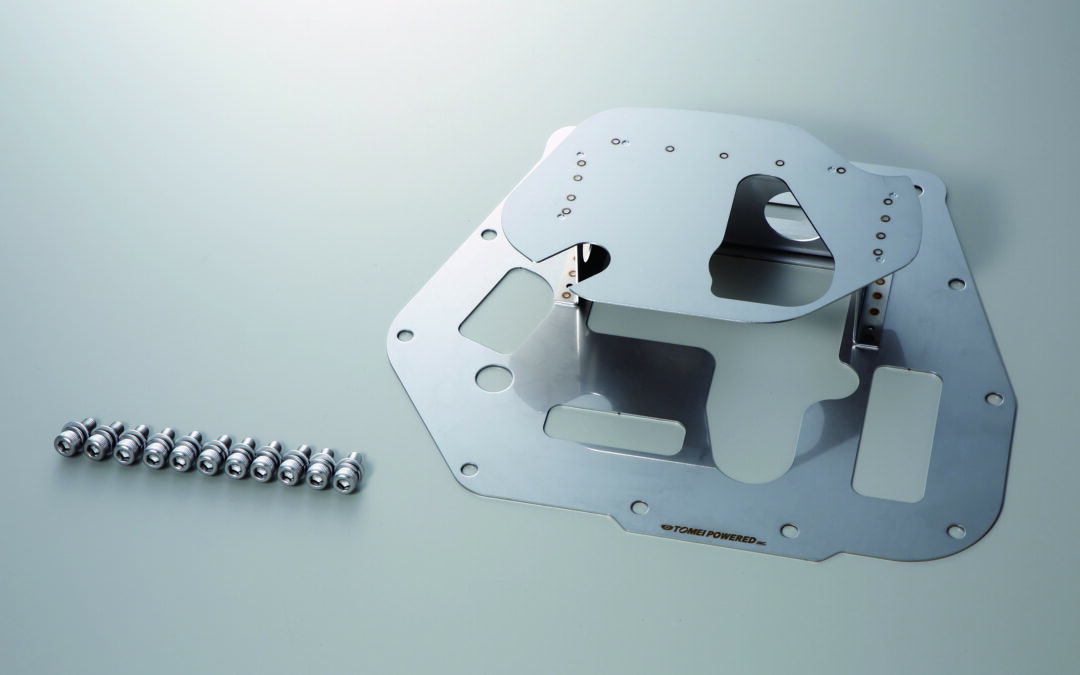

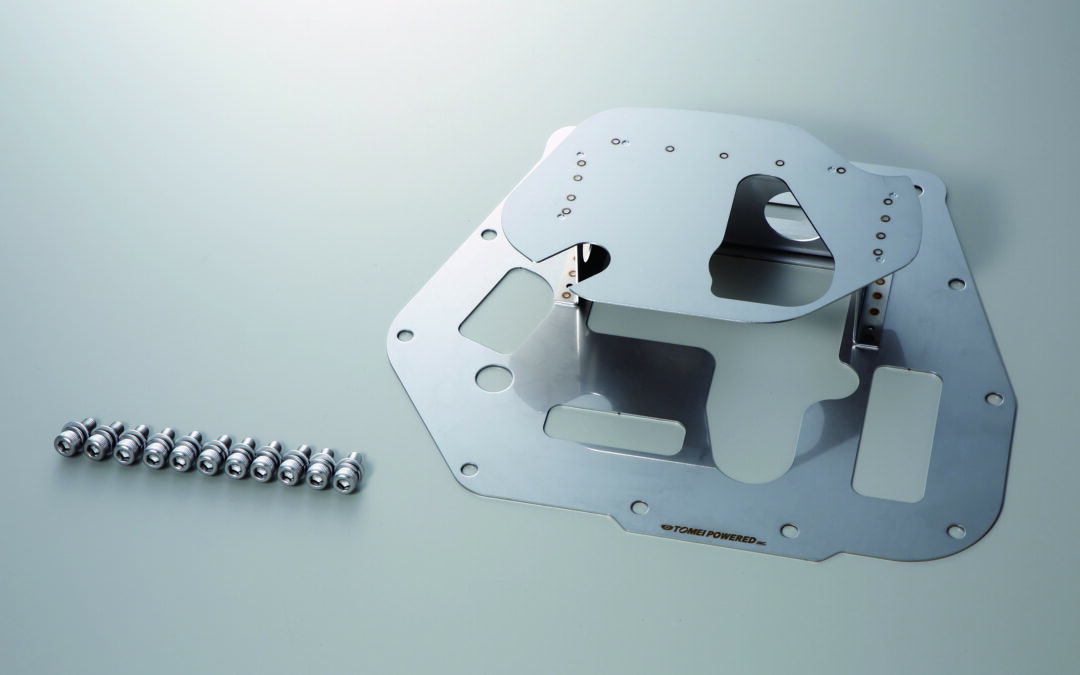

Tomei Oil Pan Baffle Plate for Subaru BRZ ZD8 and Toyota GR86 ZN8 FA24DI

Stabilize the oil supply by the multi-plated structure!

During hard acceleration, deceleration and cornering, the sudden change in inertial forces will cause the oil to jump and move around too much which causes the oil move away from the oil pickup and in turn cuts oil supply to the engine.

The TOMEI baffle plate is designed to prevent this problem from happening under any situation by the multi-plated structure and help the stable oil supply at all times.

PRODUCT INFO

| APPLICATION |

P/N |

CHF |

NOTES |

TOYOTA GR86

SUBARU BRZ |

FA24DI |

194017 |

229.-CHF |

・Baffle ASSY

・Bolts included. |

FEATURE / SPEC

| MATERIAL |

PLATE THICKNESS |

WEIGHT |

| SUS304 |

t=1.2mm |

580g |

■ UPPER PLATE CONTROLS OIL SIDEWAYS AND UPWARDS SPLASHING

The upper block-stiffening part and the lower oil-baffling part together help the stable oil supply at all times by keeping the oil from moving around too much.

【STD (w/o TOMEI baffle kit)】

The oil jumps up towards the block side along with the oil pan shape which will cause to cut the oil supply and lower the oil pressure.

【TOMEI baffle kit】

The upper plate blocks the oil jumping and keeps the oil in the oil pan which ensures the stable oil supply under any condition.

■ The lower plate keeps the oil at the oil pickup

【STD (w/o TOMEI baffle kit)】

The oil moves around due to the strong G-force towards the front, rear, left, and right which causes air cavitation in the oil line.

【TOMEI baffle kit】

The lower plate keeps the oil, which is kept in the oil pan by the upper plate, in the bottom of the oil pan where the oil pickup is.

by Hanshin-Imports | Sep 11, 2023

PRODUCT INFO

| APPLICATION |

BORE |

THICKNESS |

P/N |

CHF |

MATERIAL |

STRUCTURE |

NOTE |

| SR20DE(T) |

φ87.0 |

1.0mm |

1331870101 |

199.-CHF including Tax |

Metal |

Super Grommet |

Can not used for RNN14 |

| 1.2mm |

1331870121 |

| 1.5mm |

1331870151 |

| 1.8mm |

1331870181 |

| φ88.0 |

1.2mm |

11044R305G |

| 1.5mm |

11044R306G |

| 1.8mm |

11044R307G |

FEATURE / SPEC

■ SUPER GROMMET DESIGN

The sealing performance has been improved considerably with the super grommet,to suit these engines and has been proven to brliver excellent relibility.

|

SUPER GROMMET TYPE

The dual sealing method of the bead structure & metal grommet, provides maximum sealing for the coolant, oil & gases around the bore circumference. |

■ Heat Conductivity & The Strength of Stainless Steel

Stainless steel was chosen to be the material of choice to make the Metal Gaskets with because of the heat conductivity efficiency of the stainless steel material to evenly distribute the heat and aid with cooling. This will greatly improve reliability and reduce the chances of problems.

The natural high tensile qualities of Stainless Steel greatly helps with increasing the joint ridged of the cylinder head with the cylinder block. This helps minimize the engine from warping when under severe stress loads that performance engines go through when running high power applications. The result is improved durability and added power gains.

■ ABOUT MARKING

All our metal head gaskets are laser marked with Models, Bores, Thickness, and TOMEI POWERED INC. company name.

Since there are similar/counterfeit goods on market, please make sure logos on Gasket. |

|

●TURBO

| GASKETφ87.0 |

PSITON STDφ86.0 |

PSITON TOMEI φ86.5 |

PSITON TOMEI φ86.5(2.2L) |

| 1.0mm |

Approx.8.9 |

Approx.8.7 |

Approx.8.6 |

| 1.2mm |

Approx.8.7 |

Approx.8.5 |

Approx.8.5 |

| 1.5mm |

Approx.8.5 |

Approx.8.3 |

Approx.8.3 |

| 1.8mm |

Approx.8.3 |

Approx.8.1 |

Approx.8.1 |

| GASKETφ88.0 |

PSITON STDφ86.0 |

PSITON TOMEI φ87.0 |

PSITON TOMEI φ87.0(2.2L) |

| 1.0mm |

Approx.8.9 |

Approx.8.7 |

Approx.8.7 |

| 1.2mm |

Approx.8.7 |

Approx.8.6 |

Approx.8.6 |

| 1.5mm |

Approx.8.5 |

Approx.8.4 |

Approx.8.4 |

| 1.8mm |

Approx.8.3 |

Approx.8.2 |

Approx.8.2 |

| GASKETφ88.0 |

PSITON TOMEI φ87.5 |

PSITON TOMEI φ87.5(2.2L) |

| 1.0mm |

Approx.8.8 |

Approx.8.8 |

| 1.2mm |

Approx.8.7 |

Approx.8.7 |

| 1.5mm |

Approx.8.5 |

Approx.8.5 |

| 1.8mm |

Approx.8.3 |

Approx.8.3 |

●NA(Exclude P10&P11)

| GASKETφ87.0 |

PSITON STD φ86.0 |

| 0.6mm |

Approx.10.4 |

| 1.0mm |

Approx.10.0 |

| 1.2mm |

Approx.9.9 |

| 1.5mm |

Approx.9.6 |

| GASKETφ88.0 |

PSITON STD φ86.0 |

PSITON TOMEI φ87.0(2.2L) |

| 0.6mm |

Approx.10.4 |

Approx.12.7 |

| 1.0mm |

Approx.10.0 |

Approx.12.1 |

| 1.2mm |

Approx.9.8 |

Approx.11.5 |

| 1.5mm |

Approx.9.5 |

Approx.11.1 |

●NA P10

| GASKETφ87.0 |

PSITON STD φ86.0 |

| 0.6mm |

Approx.11.1 |

| 1.0mm |

Approx.10.6 |

| 1.2mm |

Approx.10.4 |

| 1.5mm |

Approx.10.1 |

| GASKETφ88.0 |

PSITON STD φ86.0 |

PSITON TOMEI φ87.0(2.2L) |

| 0.6mm |

Approx.11.0 |

Approx.12.7 |

| 1.0mm |

Approx.10.6 |

Approx.12.1 |

| 1.2mm |

Approx.10.4 |

Approx.11.5 |

| 1.5mm |

Approx.10.0 |

Approx.11.1 |

Values of the sample compression ratios are calculated out based on the factory spec data.

Adjustment of the compression ratio must be based on the measurement of the actual engine.

by Hanshin-Imports | Aug 31, 2023

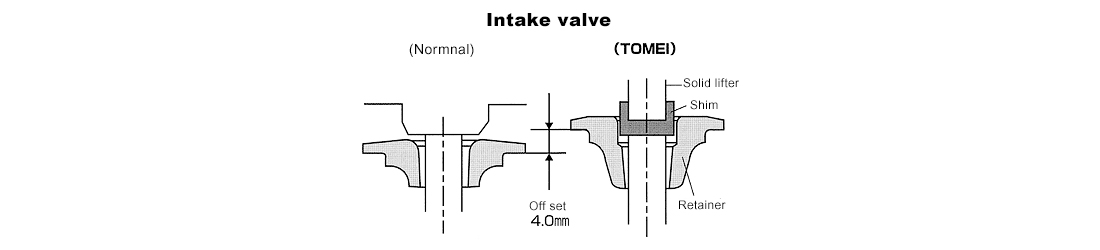

In order to make cam clearance maintenance-free and quieter operation sound, the hydraulic lash adjuster was adopted for the SR20 engine. However when aiming at higher RPM ranges and for higher horsepower output from engine modifications, it is important to improve the reliability of head system parts and to make valve drive train set correctly for the suited cam profile. So it is necessary to eliminate the use of the hydraulic lash adjusters. We have adopted the solid pivot system to enable adequate cam clearance adjustments while keeping total height of pivot of each cylinder fixed. Therefore it is possible to build a more precise head system in a shorter time compare to the other conventional methods. Improvements in the reliability and lower pricing were made possible at the same time by having reduced the number of parts required.

PRODUCT INFO

| APPLICATION |

PRODUCT |

P/N |

CHF |

CONTENTS |

| SR20DE(T) |

Solid Pivot Set |

163500 |

395CHF |

・Solid Pivotx8

・Test Shim,Test Guidex8

(t=2.70 x 4/t=2.80 x 4) |

| Solid Pivot |

163003 |

295CHF |

・Solid Pivotx8 |

| Test Shim,Test Guide Set |

163004 |

135CHF |

・Test Shim,Test Guidex8

(t=2.70 x 4/t=2.80 x 4) |

by Hanshin-Imports | Oct 13, 2022

Dual-out racing exhaust for the true performance of Z!

Designed not to sacrifice ground clearance on lowered vehicles by the optimized piping layout.

The new design joint flange on the center pipe is narrowing-free design that makes true straight-through 80mm system without any restrictions when combined with the new Ti RACING Mid Y-Pipe!

PRODUCT INFO

| APPLICATION |

P/N |

CHF |

NOTES |

| VQ35DE/HR Z33/350Z |

441004 |

2499CHF |

※FOR OFF ROAD USE ONLY. |

FEATURE / SPEC

Ti RACING Titanium Exhaust series has been designed to improve total performance while reducing the sound as much as possible to meet the sound regulation at the tracks, while EXPREME Ti series has been designed just to unleash engine’s true potential and improve the total performance.

Ti RACING Titanium Exhaust series has been designed to improve total performance while reducing the sound as much as possible to meet the sound regulation at the tracks, while EXPREME Ti series has been designed just to unleash engine’s true potential and improve the total performance.

|

|

|

|

|

|

ORIGINAL TITANIUM MATERIAL

To ensure and maintain reasonable price, supreme quality and stable supply, this product is made from TOMEI original titanium material which is refined from raw material and made into performance parts all under quality controlled environment. |

|

END TIPS

Slash-cut, 120mm slide-able end tips can adjust the rear style to suite each bumper shape and preference.Titanium blue with laser marked TOMEI logo on the end tips.They together give it the great appearance and prove the best quality. |

|

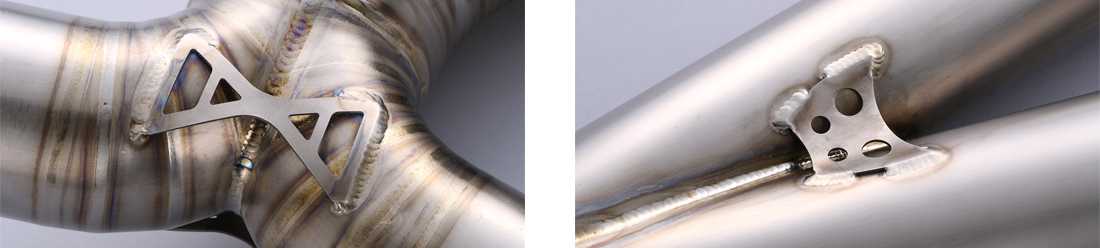

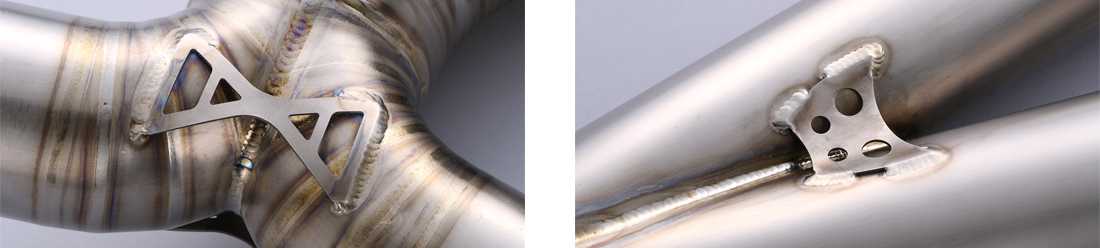

PRECISION WELDS

Titanium is known as a difficult material to weld.Its strength, long-life and beautiful appearance all prove the true quality. |

|

|

|

|

|

|

MAIN MUFFLERS

Large muffler shells eliminates problem of sound issues at the tracks without reducing performance.Stamped TOMEI logo and gradation titanium color on the mirror finished mufflers. |

|

HIGH QUALITY GLASS WOOL

Filled with even more glass wool comparing to existing EXPREME Ti series to reduce and tune the sound.High quality long filament glass wool is very durable and prevents aging deteriorations caused by continues high heat and high pressure. |

|

|

KIT CONTENTS

|

- MAIN PIPE A (1)

- MAIN PIPE B (1)

- MAIN SILENCER LH (1)

- MAIN SILENCER RH (1)

- END TIP (2)

- SILENCER BAND LH (1)

- SILENCER BAND RH (1)

- SPRING (5)

- GUSKET (1)

- CLAMP BAND φ70 (2)

- CLAMP BAND φ80 (1)

- FLANGE NUT (2)

- FLANGE BOLT (2)

- BAND RUBBER (2)

- BUTTON BOLT (4)

- BOLT SMOOTH PASTE(1)

- ALLEN KEY (1)

|

Mufflers set on each side after the split is the key to reduce the noise level while maintaining the best flowing efficiency.

The best matched pipe diameter that is proven by great amount of tries and errors increases the peak power without ruining the low-mid torque.

|

Ti RACING |

STD |

| MATERIAL |

TITANIUM |

STAINLESS/STEEL |

| MAIN PIPE DIAMETER |

Φ80S-Φ70W |

Φ60.5 |

| SUB SILENCER DIAMETER |

Φ120.0 |

105×170 OVAL |

| MAIN SILENCER DIAMETER |

Φ152 |

190x 340 W600 OVAL |

| PIPE THICKNESS |

1mm |

1.5mm |

| EXIT DIAMETER |

Φ120.0 |

Φ101.0 |

| EXIT STYLE |

SLANT CUT / DUAL OUT |

CURL TIP / DUAL OUT |

| FLANGE THICKNESS |

8.0mm |

8.0mm |

| EXHAUST TEST LEVELS |

IDLING:66.0db

4650RPM:105.5db |

IDLING:61.0db

4650RPM:86.0db |

| WEIGHT |

10.2kg |

21.0kg |

BEST WITH Ti RACING MID Y-PIPE

True-straight 80mm exhaust system can be achieved by combining with the new Ti RACING Titanium Mid Y-Pipe that is designed to connect to Ti RACING Titanium Exhaust Muffler without any narrowing in the joint.

by Hanshin-Imports | Jun 2, 2022

PISTON

Bore

(Φ) |

Pin Dia

(Φ) |

Recess |

Comp.Height

(mm) |

PistonCrownVolume

(cc) |

Weight

(g) |

| 92.5 |

23.0 |

○ |

31.0 |

18.43 |

498 |

| Top ring B×T(mm) |

Second ring B×T(mm) |

Oil ring B×T(mm) |

| 1.2×3.30 |

1.2×3.70 |

2.5×2.85 |

CRANKSHAFT

| Stroke (mm) |

Weight (kg) |

STD Stroke (mm) |

| 79.0 |

8.0 |

75.0 |

CONNECTING ROD

| Conrod |

Conrod Bolt |

Conrod Bearing |

Material |

Length

(mm) |

L.Diam×Length

(mm) |

S.Diam×Length

(mm) |

Bolt Size |

Height Under Neck

(mm) |

Inner Circum

(mm) |

Bearing Width

(mm) |

| 130.5 |

φ55×21.4 |

φ23×21.4 |

3/8-24 |

40 |

52 |

16.5 |

SNCM439 |

Compression Ration Specs

| Bore |

φ92.5 |

Gasket Thickness

(mm) |

0.7 |

8.2 |

| 1.0 |

8.0 |

| 1.2 |

7.9 |

| 1.5 |

7.7 |

| 1.8 |

7.6 |

| Gasket Bore |

93.5 |

(more…)

by Hanshin-Imports | Dec 22, 2021

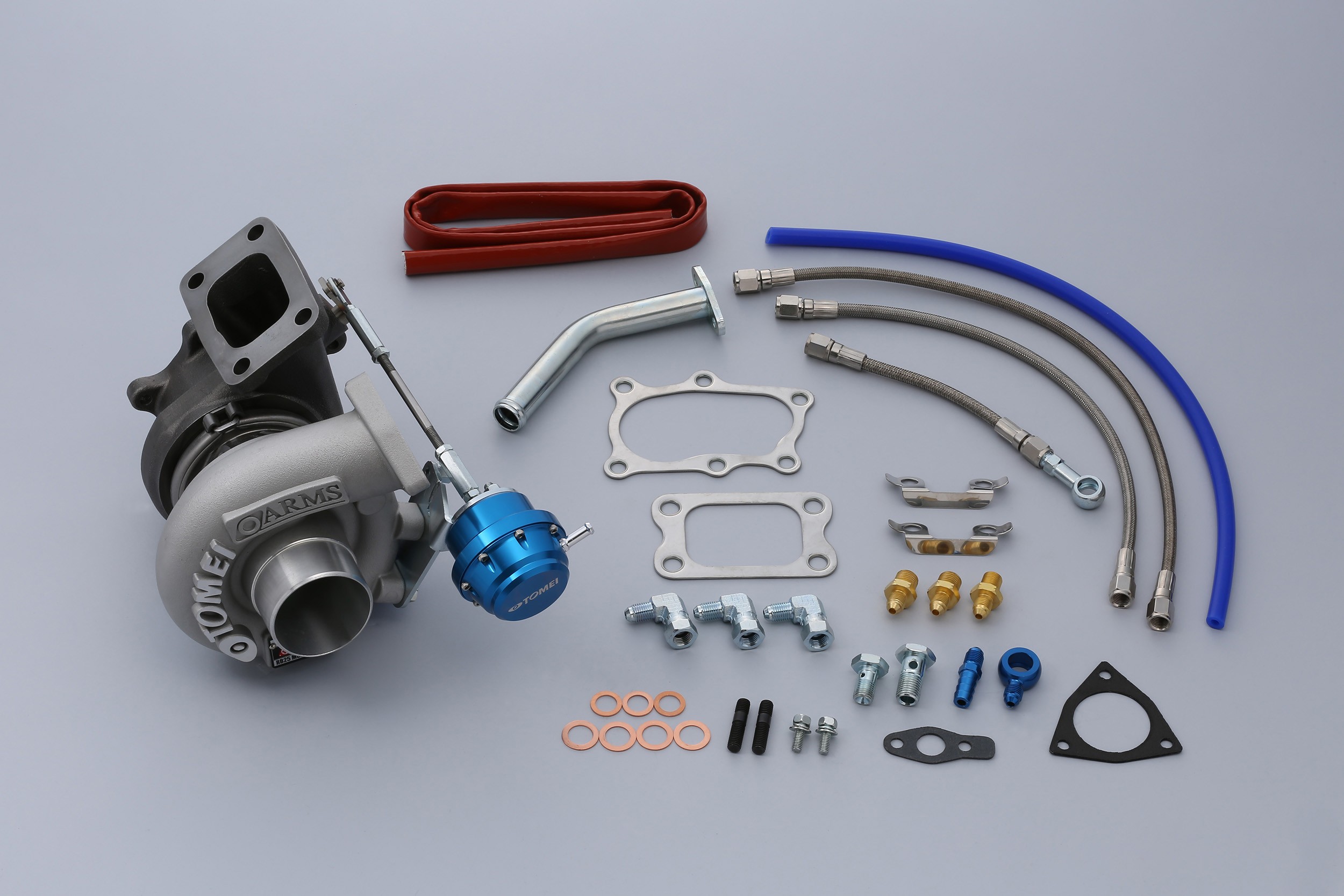

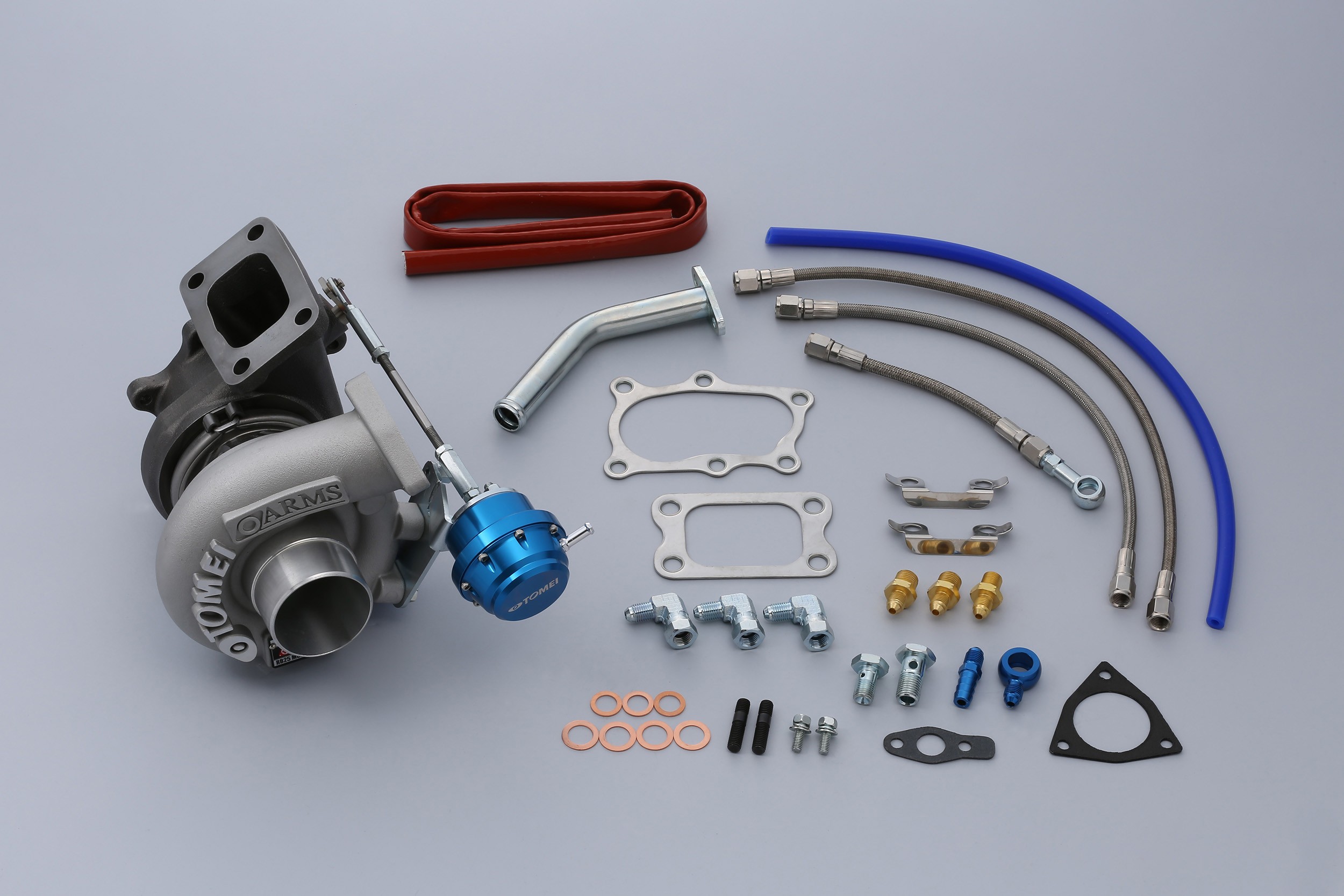

Tomei ARMS T390M/T440M SINGLE SCROLL TURBINE KIT for Subaru EJ20 and EJ25

New option of performance turbo for EJ Single Scroll!

The all new T390M turbo kit designed to best perform especially with EJ20 Single Scroll.

It comes with the same billet compressor wheel as the existing T440M turbo but covers wider range of different needs while the T440M turbo kit is mainly for tuned EJ25 and long-stroked EJ22/EJ26.

PRODUCT INFO

| APPLICATION |

TYPE |

P/N |

CHF |

NOTES |

EJ20/25 Single Scroll

※Please see the table below. |

T390M |

173034 |

2050CHF |

・TOMEI Turbo Suction Hose is also required on Impreza (GD#) and Forester (SG#).

・GDB Inetrcooler Duct (Subaru P/N: 21830AA102) is also required to install this turbo kit on Impreza (GDA) or Forester (SG#).

・Can be installed also to GC8 / SF5 by upgrading the turbo suction hose to a product with ID: 60mm at the turbo side end. |

| T440M |

173030 |

2050CHF |

FEATURE / SPEC

【Application】

| IMPREZA JDM |

FORESTER |

| GC8 |

GDA |

GDB |

GR/GV |

SF5

(STI MT) |

SG5 |

SG9 |

| A-G |

AB |

A-LINE |

| EJ207 |

EJ205 |

EJ207 |

EJ257 |

EJ205 |

EJ205 |

EJ255 |

| IMPREZA USDM |

WRX |

| GD 01-03 |

GD 04-05 |

GD 06-07 |

GR 08- |

GV 11- |

VA 15- |

| WRX |

WRX |

STI |

STI |

STI |

STI |

STI |

| EJ205 |

EJ205 |

EJ257 |

EJ257 |

EJ257 |

EJ257 |

EJ257 |

|

|

|

|

T390M

Well tuned low-mid torque that 2.0L engine can spool up smoothly to the high end range.

Stress-free and easy drivability from the street to sport driving on small tracks. |

|

T440M

Dynamic power and torque at the mid-high RPM range.

T440M is designed for steady boost even at the high end range where the stock turbo of EJ application is known to fade from around 5,500RPM.

Steady boost at the high RPM range is an essential key for tuned EJ motor. |

NEW HOUSING FOR MORE EFFICIENCY

Redeveloped from the material for more efficiency to convert the energy straight to power with better lubrication and cooling.

|

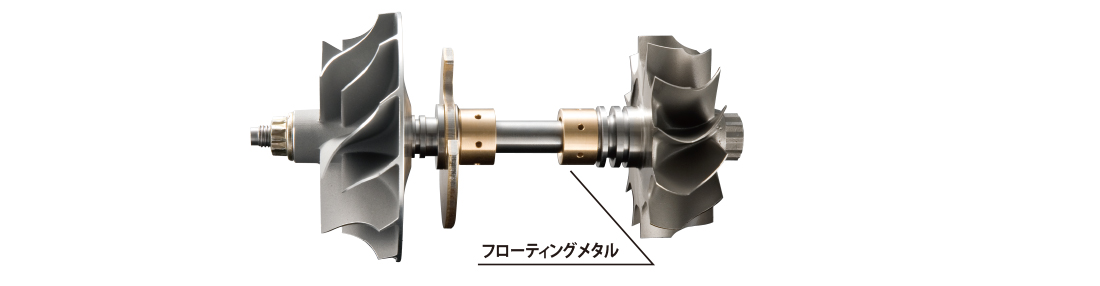

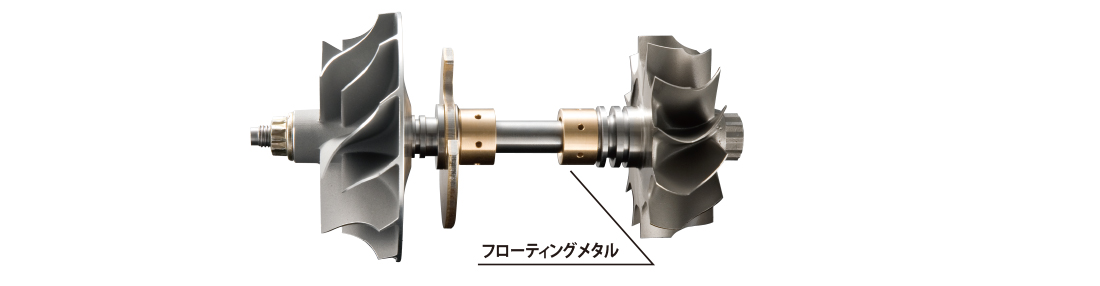

FLOATING METAL

|

|

Reinforced actuator

|

|

|

|

| High quality floating journal bearing at the center shaft. |

|

Remarkable stability under high boost. |

BOLT-ON APPLICATION

The ARMS series turbo kits all come supplied with all the required gaskets and fitting, no modifications required.

1 YEAR WARRANTY

The T390M/T440M Turbo Kit comes with a 1 year limited warranty after purchase.

■ HOW TO REGISTER

|

TRIM |

INNER DIA. |

OUTER DIA. |

BLADES |

| ARMS T390M |

60 |

52.6 |

68.0 |

6/6 |

| ARMS T440M |

56 |

56.2 |

75.0 |

6/6 |

The all new, forged aluminum billet compressor wheel increases even more efficiency and at the same time reduces surging that is one of the well known problems on tuning especially with AVCS applications.

The all new, forged aluminum billet compressor wheel increases even more efficiency and at the same time reduces surging that is one of the well known problems on tuning especially with AVCS applications.

|

TRIM |

OUTER DIA. |

EXIT DIA. |

BLADES |

| ARMS T390M |

76.9 |

56.0 |

49.1 |

12 |

| ARMS T440M |

77.4 |

61.5 |

54.1 |

11 |

- 【T390M+EJ20 S/S】Superior balance of response and power

Well balanced for quick response from the low range to the top power at the high RPM range!

- 【T440M+EJ22 S/S】Outstanding peak power and performance

Simply for more power making the most of EJ22.The dynamic acceleration is like a beast.

- 【T440M+EJ25 S/S】Torquey and powerful

Fat and pushing torque with a whole different level of power from the large displacement.

Steady boost at all range

Quick spool eliminating turbo surging, superior smoothness straight up to the high end RPM range.

by Hanshin-Imports | Sep 14, 2021

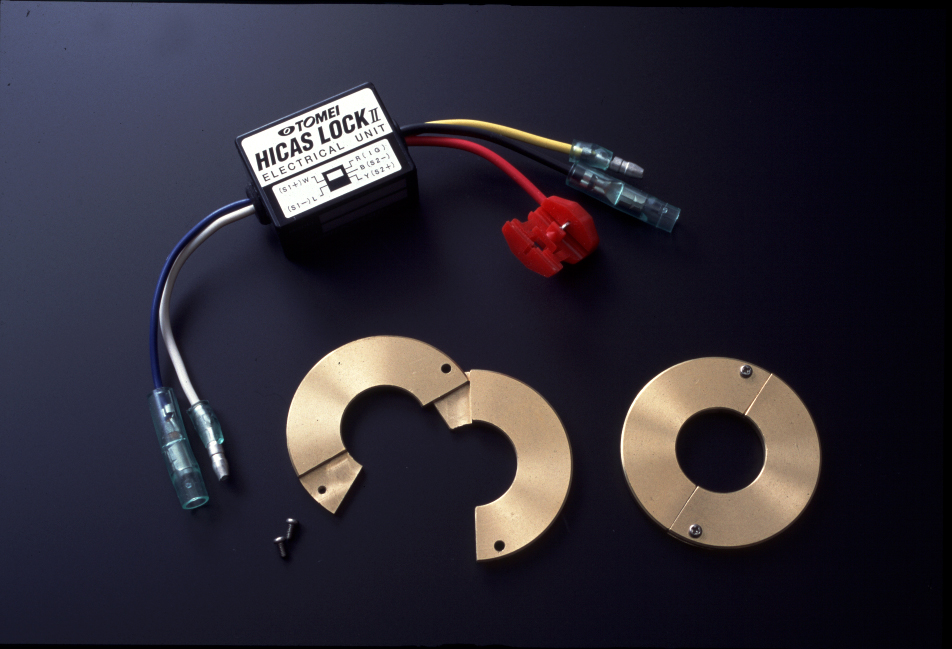

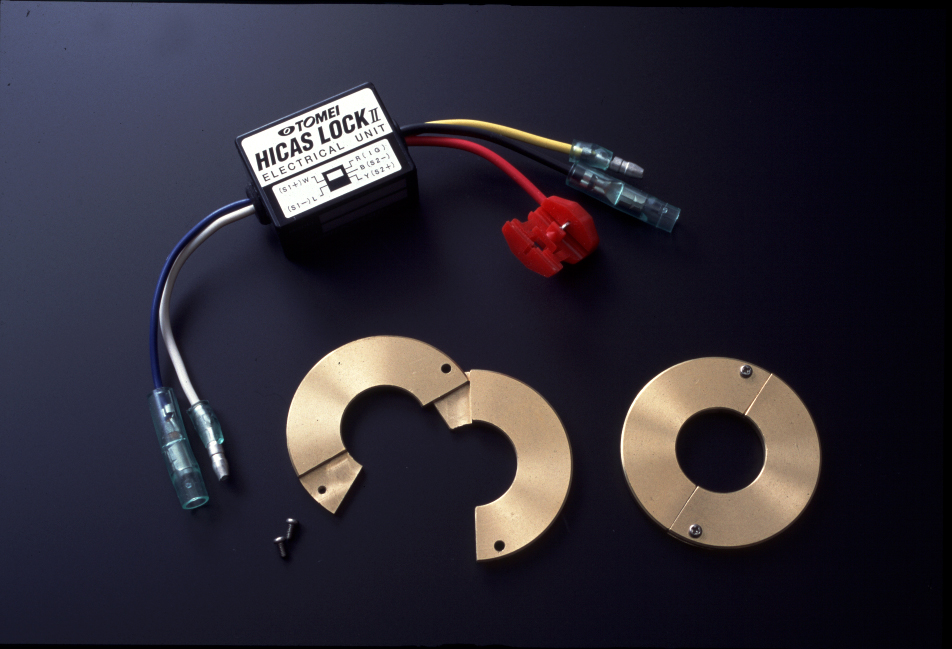

Tomei HICAS LOCK and deactivation kit

Deactivate and lock your Hicas system to prevent it from interfering with your driving and get a more direct steering feel. The kit works on the following cars:

| MODEL |

APPLICATION |

P/N |

Price CHF |

NOTE |

| HICAS II |

・ KS13 Silvia

・ KRS13 180SX

・ HCC33 Laurel

・ CA31 Cefili |

56000S210 |

149CHF |

|

| SUPER HICAS |

・ KPS13 Silvia

・ KRPS13 180SX

・ HCR32 Skyline GTS

・ BNR32 Skyline GT-R

・ (G)CZ32 Fairlady Z Before M/C(~93.3)

・ PBY32 Cedric/Grolia |

| Electrical SUPER HICAS |

・ ECR33 Skyline GTS/GTS25t

・ BCNR33 Skyline GT-R

・ ER34 Skyline 25-GT-T

・ CS14 Silvia

・ S15 Silvia

・ (G)CZ32 Fairlady Z After M/C(93.9~)

・ HBY33 Cedric/Grolia

・ GCC34 Laurel |

by Hanshin-Imports | Feb 5, 2021

We chose to use Phosphor Bronze (Cn-Sn-P alloy) to make our Valve Guides, for its highly tensile and superior heat transferring ability, which is vital in high power and high RPM outputting engines. Since race engines these days require more power at higher RPM use , these engines now experience more extreme heat conditions. These conditions will increase the deterioration rate on these valve train related components. The Phosphor Bronze material has exceptionally lower friction and the best possible clearances can be maintained, which will reduce the stress on the valve train assembly, prevent seizures and cracking under high-stress loads.

PRODUCT INFO

| APPLICATION |

IN/EX |

P/N |

CHF |

| CA18DE(T) |

SET |

163304 |

289CHF |

|

|

|

|

|

FEATURE / SPEC

| MATERIAL |

5191(Cn-Sn-P alloy) |

| TENSILE STRENGTH |

590~685(N/㎜2) |

| HARDNESS |

180~230(HB) |

Still since the product will be used for extreme conditions, it will still require additional regular maintenance and periodical checks. The product can wear out faster under certain conditions. Some examples of the abnormal conditions are as follows.

■The rocker arm type assemblies will apply more lateral pressure, which will increase the wear rate. If the stem wall of the valve is rough, it will also contribute to the increased wear rate.

■Using high lift, aggressive camshafts will also increase the wear rate.

■Excessive buildup of carbon will also hinder performance and increase wear rate. When there’s a small opening at the end, it will increase the carbon buildup rate as a funnel effect.

■The results from Valve Spring surging will cause the Valve to move on an angle. This will cause both ends to open up and create deformation. Then carbon can enter the valve guides more which will increase the wear rate.

■A defective seat cut. When the seat cut’s centerline across the main 45 degree face is offline from the valve stems centerline by more than 0.01mm, this can cause increased abnormal wear rate.

■If the clearance is not within the correct 0.03-0.04mm range. The Valve will rub against the guides inner wall, this degree angle in relation to the seat cut will cause it to shift by 0.01mm more than the clearance values. The guide will take the lateral pressure point and open up the opening. The buildup of carbon will increase in the newly formed gaps.

■A worn out used Valve. It’s possible to cut down by using the part that has not worn out the stem when changing to a high lift cams. The guides can wear out when the inappropriate clearances are made. (About 0.01mm out of clearance).

■The Valve design is defective. The difference from the dilatability and the guide being worn out abnormally is when the valve that is made with different alloys, will contribute with a faster deterioration.

by Hanshin-Imports | Feb 5, 2021

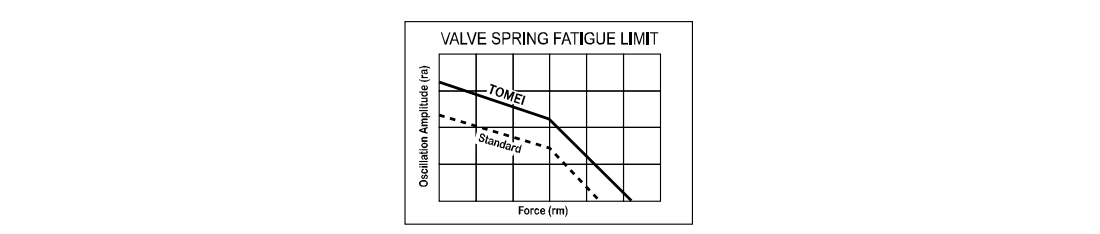

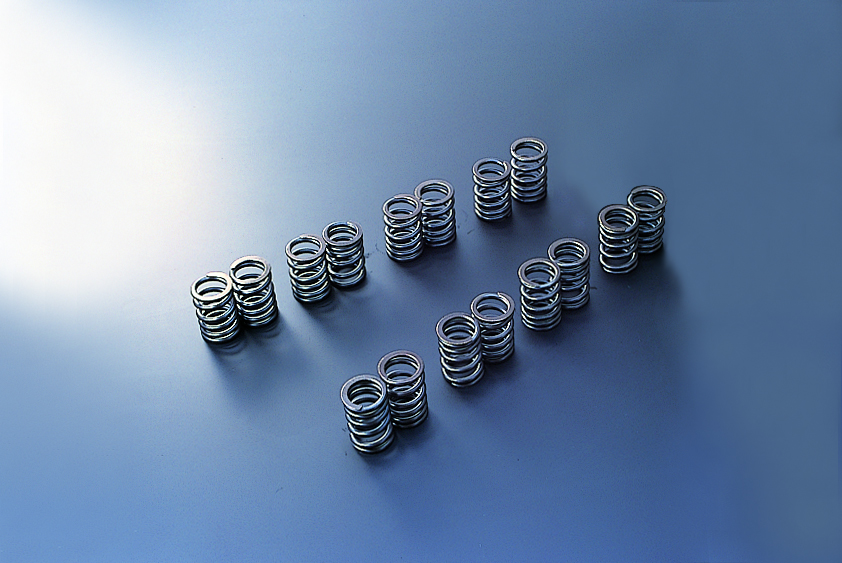

High quality designed springs is required to transfer the exact movement of the camshaft to the valves at high engine speeds on high performance engines. The TOMEI products are always engineered with precision in mind to suit the user’s needs. So with this in mind careful choices in material selection is made with surface coating and other technologies. Then the pre-production products are put through an extensive testing program for checking durability, quality and performance. We spend time and money to help you save your valuable time and money.

PRODUCT INFO

| APPLICATION |

COMPATIBLE LIFT(mm) |

P/N |

CHF |

NOTES |

| CA18DE(T) |

~10.35 |

13203R410 |

289CHF |

|

FEATURE / SPEC

| DIA METER |

FREE LENGTH(mm) |

SET LENGTH(mm) |

LIFT LENGTH(mm) |

COMPRESSED LENGTH(mm) |

SET LOAD(kgf) |

LIFT LOAD(kgf) |

MATERIAL |

PROCESS |

COLOR ID |

| Φ3.90 |

41.0 |

35.0 |

25.0 |

24.0 |

24.2±7% |

80.6±7% |

SWOSC-VX |

Nitride |

Blue |

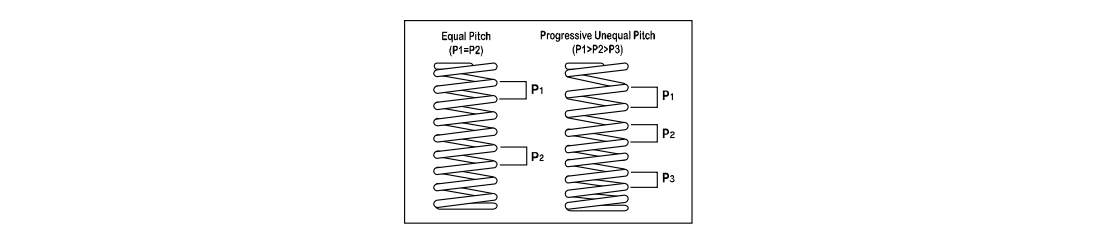

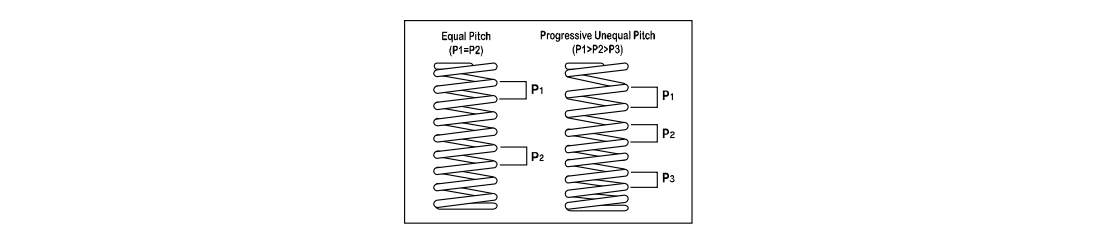

■ Multi Coil Unequal Pitch Springs

By combining several steps of spring rates into the one spring and vibration frequency becomes amazingly high. This greatly minimizes resonance and the chances of surging.

■ Advanced Oil Tempered Chromium-silicone Alloy Steel Core

Oil tempered chromium-silicone alloy steel wire is used which is considered to be the best material for springs for performance applications and evolved it even further. Combined with a new optimized design, not only did we make it tougher, we also succeeded in suppressing valve jumps or bounce even when raising the engines speeds RPM limit.

■ Shot Peening

A process that strikes many small steel balls onto the surface of the spring at high speeds is made to enhance the surface of the spring to raise its fatigue limit. Although it has been carried out earlier during the manufacturing process.

■ Warm Setting

The process that is adding higher loads beyond the actual limits to the highly heated spring. This will modify its shape and keep it permanently fixed. We succeeded in securing the highest performance over a long period of time while preventing sagging.

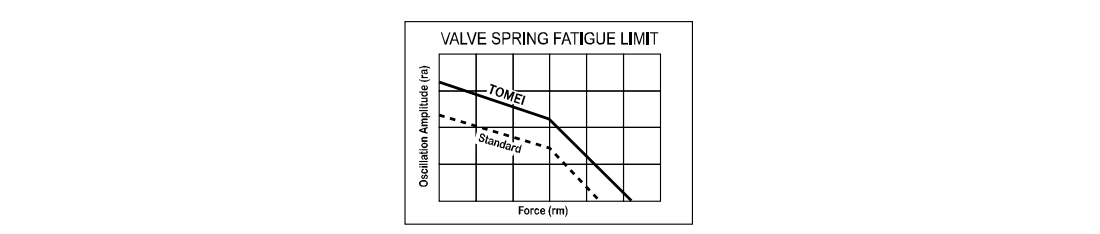

■ Nitriding

The surface treatment method for making nitrogen permeates the spring and gives it large surface compression repulsion. This method was chosen to raise the fatigue limit to suit the demands or running high lift camshafts. The dangers of spring failure is greatly reduced with the 1.5 times increase in the springs fatigue limit with the combined use of Oil tempered chromium-silicone alloy steel wire and Nitriding. This is how our valve springs are suitable for use on extreme engine speed conditions of super-high revs exceeding 10,000 RPM which had not been previously possible with high lift camshafts.

by Hanshin-Imports | Jul 21, 2020

Durability & Reliability, The Answer for All Professionals!!

When tuning engines for higher power output and high RPM the bearings are subjected to extreme load conditions. These harsh conditions require the bearings to be able to cope with excessive loads and stress conditions. The TOMEI Competition Bearing series are designed for fatigue resistance, durability, effective lubrication and resistance to scoring. Designed for use on engines that will be outputting 1,000 HP and at over 10,000RPM. These advanced designed bearings are suitable for the serious professionals in mind whom need results. We also have 3 grades available on all engine applications.

PRODUCT INFO

| APPLICATION |

PART |

GRADE |

SIZE |

INDEICATION

COLOR |

STD

GRADE |

P/N |

CHF |

QTY

per car |

| ENGINE |

MODEL |

RB26DETT

RB25DE(T) |

R32

R33

R34 |

MAIN

INNER |

Upper/

Lower

Set |

A |

1.818~1.821 |

Black |

0 |

126100 |

49CHF |

6sets |

| B |

1.821~1.824 |

Green |

1 |

126101 |

| C |

1.824~1.827 |

Yellow |

2 |

126102 |

| D |

1.827~1.830 |

Red |

3 |

126103 |

MAIN

CENTER |

Upper/

Lower

Set |

A |

1.818~1.821 |

Black |

0 |

126104 |

152CHF |

1set |

| B |

1.821~1.824 |

Green |

1 |

126105 |

| C |

1.824~1.827 |

Yellow |

2 |

126106 |

| D |

1.827~1.830 |

Red |

3 |

126107 |

| CONROD |

Upper/

Lower

Set |

A |

1.500~1.503 |

Black |

0 |

127100 |

46CHF |

6sets |

| B |

1.503~1.506 |

Green |

1 |

127101 |

| C |

1.506~1.509 |

Yellow |

2 |

127102 |

FEATURE / SPEC

■ These products are designed and produced in cooperation with Australia’s ACL Bearing Company, which supplies engine bearings and various engine components as OEM to various automotive manufacturers.

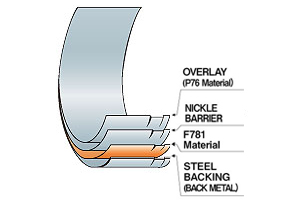

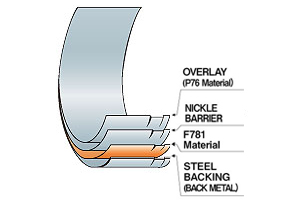

MATERIALS

|

The combination of these material enhancements optimize bearing performance under high loads and temperatures.

OVERLAY (P76 Material)

The P76 material is used for it’s superior abrasion and fatigue resistance. The elimination of the tin flash plating improves the heat transfer through the bearing.

F781 Material

The F781 material is used on connecting rod bearings for high performance engines. It has a hardened steel backing to improve the support of the bearing lining and assist bearing retention in the housing. |

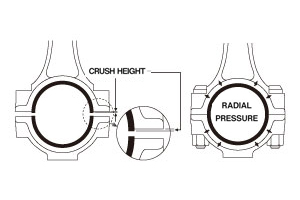

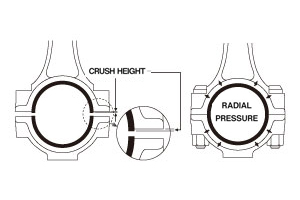

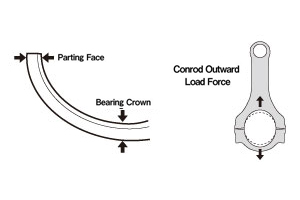

CRUSH

|

The Competition Bearing Series are designed with an increased crush (i.e. extra bearing length of typically 0.100-0.175mm). The extra crush improves the retention of the bearing in it’s housing.

Crush Height: The crush height is based on the bearing being a fraction longer than the housing seating so that a small section protrudes above the rod bore parting surface. When the rod halves are drawn together, the inserts touch before the halves, thus forcing the inserts tightly into place. |

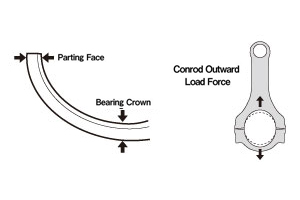

ECCENTRICITY

|

The wall thickness at the crown of the shell is thicker than the wall at 3/8″ down from the parting face. These Competition Bearing Series have an increased amount of eccentricity to compensate for the bearing housing bore elongation in extreme conditions and to help create an effective hydrodynamic oil film. |

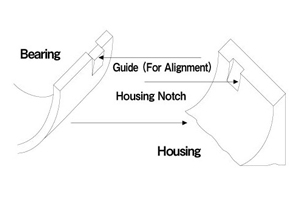

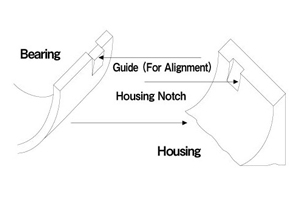

LOCATING TANGS (NOTCHES)

|

These Notches help with bearing alignment during fitment. They do not hold the bearings in place during operation, that is the function of “Crush”. |

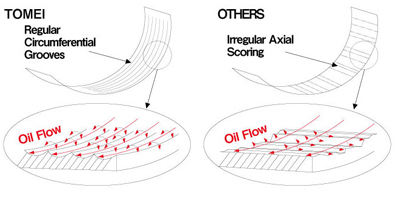

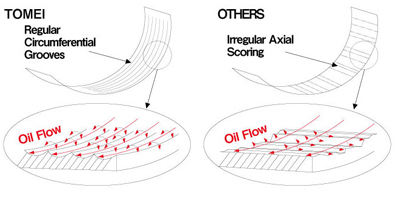

BORED SURFACE

|

The bore bearing surface finish method helps promote effective oil flow and to maintain adequate lubrication for both the bearings and other moving parts. |

BORED SURFACE

The design of the oil grooves on the lower main bearing shell is always a trade off between oil supply to the Conrods and the bearings load carrying capacity. These TOMEI Competition Bearings generally have a 3/4 groove to give optimum balance of oil flow whilst keeping optimum load carrying capacity.

The reason why TOMEI Competition Bearing Series do not have the final tin flash plating.

General standard grade bearings will have a Tin flash plating over the entire bearing to give them the grey silver finish. Since these bearings are designed for high end race purposes, the use of the final tin flash is not required as it gives no added benefit. Therefore, these bearings may show different colouring, which is normal.

The disadvantages of using the Tin Flash Plating are 1. Heat dissapation will be reduced. 2. The tin on the bearing back can act as a lubricant at high temperatures, and reduce the friction between the bearing and its housing. 3. At high loads and temperatures the tin plating on the bearing back can break down and “pool” to create hot spots.

To ensure the optimum bearing performance, the TOMEI Competition Bearing Series has not adopted this type of final tin flash plating. Thus the appearance of uneven colouring on our bearings. This poses no issues with performance and bearing efficiency so please do not be alarmed by it. There is a protective oil coating administered during packaging for protection against the elements. Please remove this oil coating prior to use. The protective oil coating will allow the bearings to have a storage shelf life of up to 3 years.

by Hanshin-Imports | Nov 29, 2019

Left:for EVO I~III / IV~VI Right:for EVO VII~IX

During the development of the ARMS turbines we also checked the suitable fuel setup, camshafts, compression ratio and collected the right data and setup with the REYTEC and TOMEI ECU. We found the best balance not only for the engine bench dyno but also for the daily driven Sports car use. The data collected during R&D proved to be the best balanced all round performance for street use and even at event days from Time Attack to Drift after being analysised from data logging.

PRODUCT INFO

| APPLICATION |

ENGINE |

P/N |

CHF |

NOTES |

| Evo.1~3 |

4G63 |

191170 |

199CHF |

|

| Evo.4~6 |

191134 |

| Evo.7~9 |

191186 |

285CHF |

|

|

Turbine Protection |

Boost Up |

Engine Failure |

Fuel stability |

| Stock Blow Off |

○ |

× |

○ |

○ |

| Without Blow Off |

× |

○ |

△ |

△ |

| Open Air Release |

○ |

○ |

△ |

△ |

| TOMEI |

○ |

○ |

○ |

○ |

by Hanshin-Imports | Nov 29, 2019

| TYPE |

APPLICATION |

DURATION(°) |

MAX VALVE LIFT(mm) |

IN/EX |

P/N |

CHF |

NOTE |

| ENGINE |

MODEL |

IN |

EX |

IN |

EX |

|

4G63 |

EVO I – III |

260 |

260 |

10.70 |

10.20 |

IN & EX Set |

143032 |

749.60CHF |

|

| EVO IV – VI |

143033 |

|

EVO VII-VIII

Air Trex |

143038 |

GT-A is available |

|

| EVO IX |

143058 |

999CHF |

|

| R |

EVO IV – VI |

270 |

270 |

10.70 |

10.20 |

IN & EX Set |

143066 |

749.60CHF |

|

| EVO VII-VIII |

143067 |

| EVO IX |

143068 |

999CHF |

※PRESET VALVE TIMING

※STOCK VALVE SPRING COMPATIBLE

※MIVEC is available for EVO9

by Hanshin-Imports | Nov 29, 2019

Left:for EVO I~III / IV~VI Right:for EVO VII~IX

During the development of the ARMS turbines we also checked the suitable fuel setup, camshafts, compression ratio and collected the right data and setup with the REYTEC and TOMEI ECU. We found the best balance not only for the engine bench dyno but also for the daily driven Sports car use. The data collected during R&D proved to be the best balanced all round performance for street use and even at event days from Time Attack to Drift after being analysised from data logging.

PRODUCT INFO

| APPLICATION |

ENGINE |

P/N |

CHF |

NOTES |

| Evo.1~3 |

4G63 |

191170 |

199CHF |

|

| Evo.4~6 |

191134 |

| Evo.7~9 |

191186 |

285CHF |

|

|

Turbine Protection |

Boost Up |

Engine Failure |

Fuel stability |

| Stock Blow Off |

○ |

× |

○ |

○ |

| Without Blow Off |

× |

○ |

△ |

△ |

| Open Air Release |

○ |

○ |

△ |

△ |

| TOMEI |

○ |

○ |

○ |

○ |

by Hanshin-Imports | Sep 6, 2019

Make the most of the beast with this all new, best and super high flow racing exhaust! Precisely tuned for the pure racing sound while keeping the moderate volume.

The Ti RACING competition exhaust system is now offered for those R35 owners demand the best of the best.

Catless, straight-through design all the way after the front pipes optimizes the exhaust flow for true performance while maintaining the elegance of the R35 exhaust note.

PRODUCT INFO

| APPLICATION |

P/N |

CHF |

NOTES |

| R35 GTR |

441007 |

5365.- |

・FOR OFF ROAD USE ONLY.

Does not fit MY 2017 and up except Pure Edition. |

FEATURE / SPEC

Ti RACING Titanium Exhaust series has been designed to improve total performance while reducing the sound as much as possible to meet the sound regulation at the tracks, while EXPREME Ti series has been designed just to unleash engine’s true potential and improve the total performance.

|

|

|

|

|

|

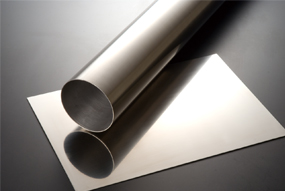

ORIGINAL TITANIUM MATERIAL

To ensure and maintain reasonable price, supreme quality and stable supply, this product is made from TOMEI original titanium material which is refined from raw material and made into performance parts all under quality controlled environment. |

|

END TIPS

Blue burnt titanium color and laser marked TOMEI logo on the end tips.These together give it the great appearance and prove the best quality. |

|

PRECISION WELDS

Titanium is known as a difficult material to weld.Its strength, long-life and beautiful appearance all prove the true quality. |

|

|

|

|

|

|

MAIN MUFFLERS

Large muffler shells eliminates problem of sound issues at the tracks without reducing performance.Stamped TOMEI logo and gradation titanium color on the mirror finished mufflers. |

|

HIGH QUALITY GLASS WOOL

Filled with even more glass wool comparing to existing EXPREME Ti series to reduce and tune the sound.High quality long filament glass wool is very durable and prevents aging deteriorations caused by continues high heat and high pressure. |

|

MID PIPE

Sub mufflers in the cat-less mid pipes to reduce the volume as much as possible without reducing performance to meet the growing problem of sound issues at the tracks. |

KIT CONTENTS

|

- MAIN PIPE A (1)

- MAIN PIPE B (1)

- MID Y PIPE (1)

- SUB MUFFLER RH (1)

- SUB MUFFLER LH (1)

- MAIN MUFFLER RH (1)

- MAIN MUFFLER LH (1)

- END TIP (2)

- END TIP (2)

- MUFFLER BAND RH (1)

- MUFFLER BAND LH (1)

- CLAMP BAND φ102 (2)

- CLAMP BAND φ80 (4)

- GUSKET (2)

- BUTTON BOLT (4)

- SPRING (4)

- MUFFLER BAND RUBBER (2)

- FLANGE BOLT (2)

- FLANGE NUT (2)

- SENSOR PLUG (2)

- SEAL WASHER (2)

- ALLEN KEY (1)

- BOLT SMOOTH PASTE(1)

|

SPEC

The straight-through sub mufflers in the catless center piece reduces the sound despite the large diameter 80-102-80mm to meet the growing problem of sound issues at the tracks without reducing performance. Full titanium made, true straight structure without any narrowing or restriction reduces 14.5kg of weight compared to the factory exhaust.

|

Ti RACING |

STD |

| MATERIAL |

TITANIUM |

STAINLESS |

| MAIN PIPE DIAMETER |

Φ80W-φ102S-φ80W |

Φ54W-φ70S-φ60.5W |

| MUFFLER DIAMETER |

Φ152 |

Φ105-φ195 OVAL |

| PIPE THICKNESS |

1mm |

1mm |

| EXIT DIAMETER・EXIT STYLE |

Φ102-SLASH CUT |

Φ130-CURL TIP |

| FLANGE THICKNESS |

8.0mm |

6.0mm |

| EXHAUST TEST LEVELS |

IDLING:74.5.5db

4800RPM:109.5db |

IDLING:65.0db

4800RPM:95.5db |

| WEIGHT |

16.1kg |

30.6kg |

by Hanshin-Imports | Sep 4, 2019

To truly enjoy the FA20 is to extract the most from it in NA form. So maximum weight reduction is an essential part of it. This product is specifically designed for competition use. With the absence of a catalytic converter, the pipes made from Titanium, this drastically reduces the overall weight to compliment the power gains.

When fitted to a car that has a forced induction setup, it greatly enhances the performance gains with the improved exhaust flow efficiency. This is one of the key products to extract the performance potential of the 86/BRZ/FR-S.

PRODUCT INFO

| APPLICATION |

P/N |

CHF |

NOTES |

86/BRZ/FR-S

FA20 6MT |

431005 |

670.-TTC |

※Designed for true competition off road use only. |

FEATURE / SPEC

KIT CONTENTS

- STRAIGHT MAIN PIPE F

- STRAIGHT MAIN PIPE R

- GASKET F

- CLAMP BAND

- A/F SENSOR PLUG

- COPPER WASHER

|

TOMEI |

STD |

| MATERIAL |

TITANIUM |

IRON |

| PIPE DIAMETER |

Φ60.5 |

Φ60.5 |

| PIPE THICKNESS |

1mm |

1.5mm |

| FLANGE THICKNESS (F) |

8.0mm |

10.0mm. |

| FLANGE THICKNESS (R) |

8.0mm |

8.0mm |

| WEIGHT |

1.4kg |

5.5kg |

|

4.1kg DROP! |

|

|

|

|

|

【FRONT SIDE】

Precision lightweight Titanium flange. |

|

【REAR SIDE】

Utilizes the same round Φ60.5 diameter flange design as the std item. |

|

【2 SECTION LAYOUT】

2 section pipe layout for ease of installation and a Mikalor damp band. |

|

|

|

|

|

|

|

|

|

|

【BRACKET】

Lightweight Titanium is used. With a base plate to distributes stress. |

|

【A/F SENSOR BOSS】

Comes equipped with an A/F sensor boss for convenience when tuning. |

|

|

by Hanshin-Imports | Jun 3, 2019

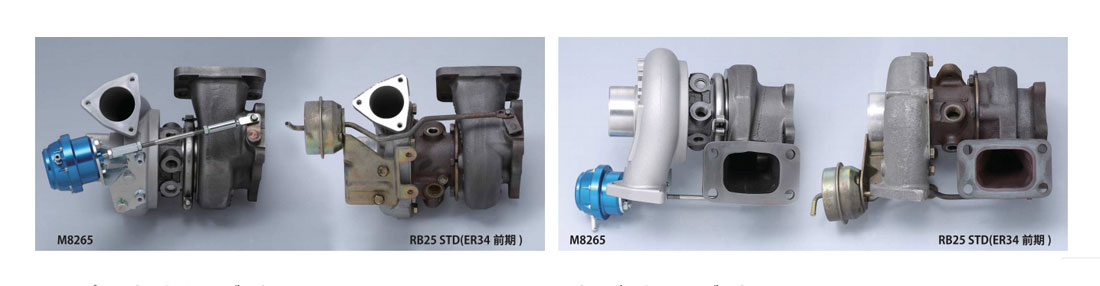

ARMS M8265 TURBINE KIT RB25DETa

TURBO CHARGER

Bolt-on, perfect balanced turbo for RB25!

ARMS M8265 guarantees amazing performance for all RB25DET no matter drift competition or street daily driver!

PRODUCT INFO

| APPLICATION |

TYPE |

P/N |

CHF |

NOTES |

R33/R34 C34/C35/WC34

RB25DET |

M8265 |

173029 |

2070.- TTC |

|

FEATURE / SPEC

Flat Primary Exhaust Pressure

The boost build up is neither sluggish nor abrupt; we have designed this to be natural and smooth.This characteristic provides a stress free driving experience with easy vehicle operation.

Unleash the true performance of ARMS M8265

Peripheral parts such as Poncam, Cam Gear, Head Gasket, Forged Piston, Down Pipe etc… These parts make synergistic effect when combined with the ARMS Turbo.

100% BOLT ON

The ARMS series turbo kits all come supplied with all the required gaskets and fitting accessories for a true bolt on application out of the box. So it can be installed immediately without the need to hunt for other parts.

FLOATING METAL

A Floating Bearing (Journal Bearing) was adopted for use on the shaft.

1 YEAR WARRANTY

|

The ARMS RB25 M8265 Turbine Kits come with a 1 year limited warranty after the product has been registered with Tomei Powered shortly after purchase. |

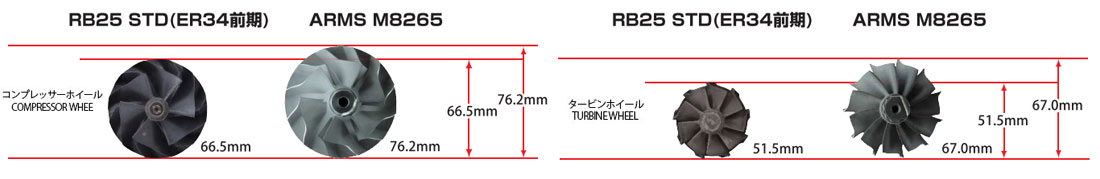

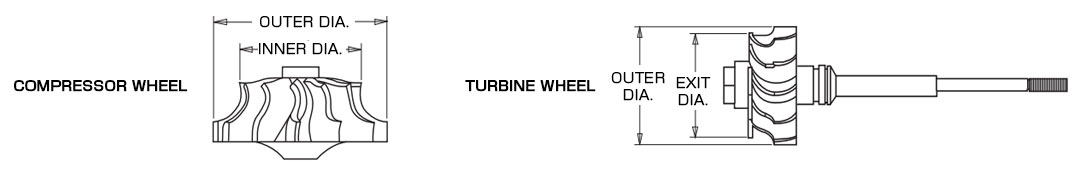

SPEC

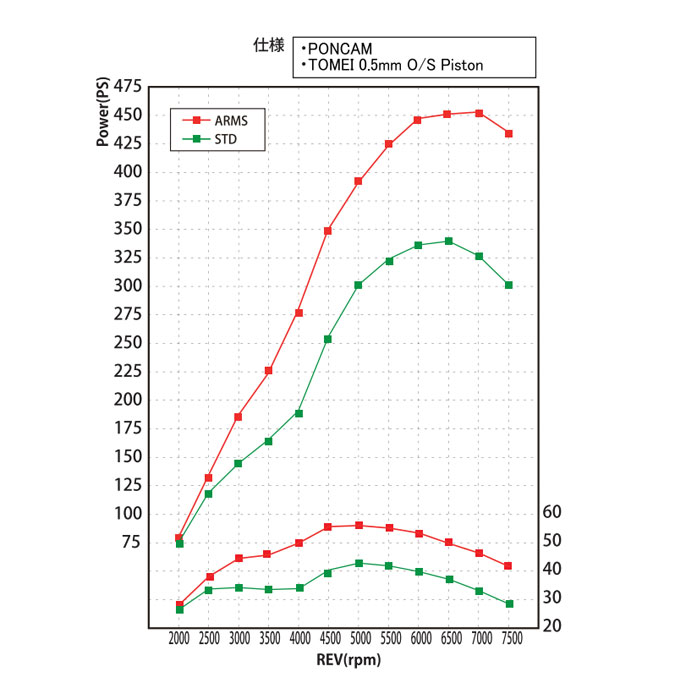

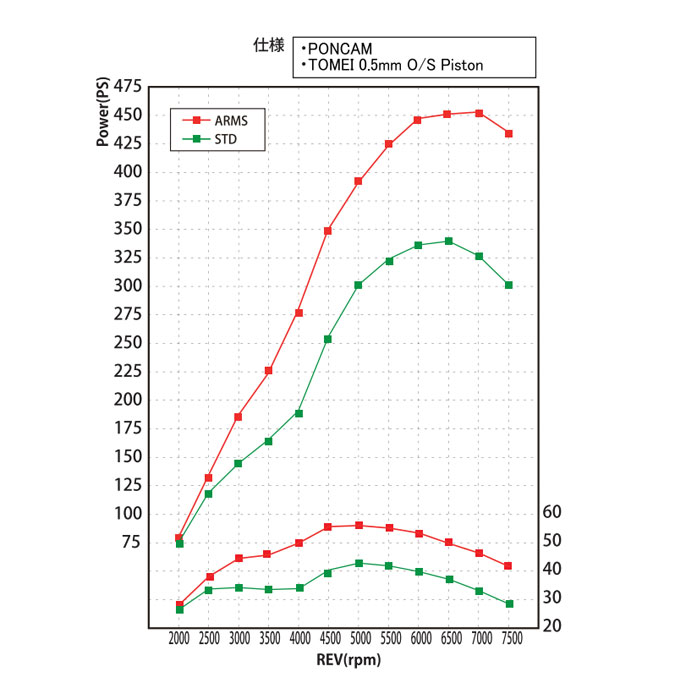

DATA

- MAINTAINING POWER AT HIGHER TUNING

With the stock displacement, you can expect to see good power from 6000rpm and higher. But with the increase in the engines displacement, even more potential gains are possible.

![Tomei Kit Poncam RB25DE[T]](https://hanshin-imports.ch/wp-content/uploads/2020/12/products-4009.jpg)

by Hanshin-Imports | Mar 19, 2019

|

Type

|

Application

|

(IN)

|

(EX)

|

Lift (IN)

|

Lift (EX)

|

P/N

|

CHF

|

|

R33(phase 1),WGNC34(phase 1),C34

|

256°

|

256°

|

8.50

|

8.50

|

143020

|

792,01.- HT

(853.-TTC)

|

|

R33(phase 2) WGNC34(phase 2)

|

143050

|

|

A

|

R34,WGNC34 (Phase 2)

NEO 6(RB25DE)

|

252°

|

252°

|

9.15

|

9.15

|

143046

|

|

B

|

260°

|

260°

|

143023

|

by Hanshin-Imports | Mar 19, 2019

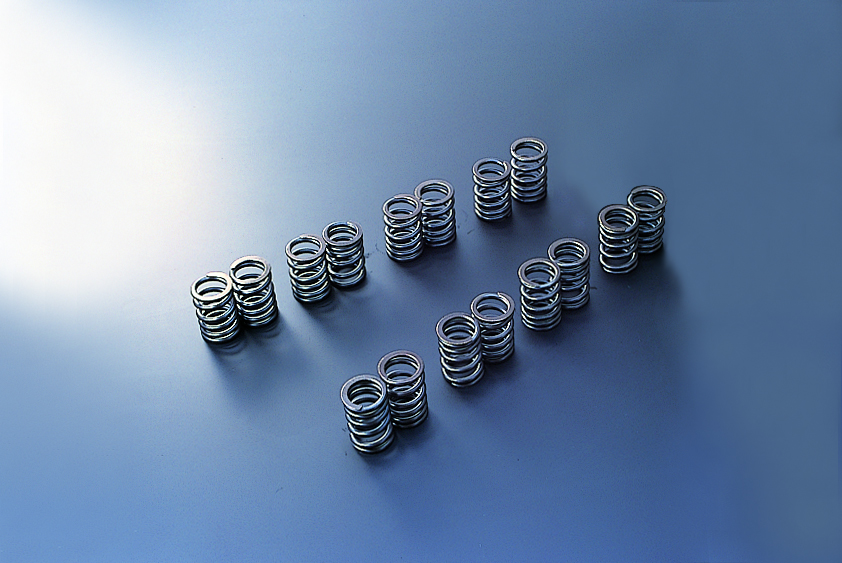

High quality designed springs is required to transfer the exact movement of the camshaft to the valves at high engine speeds on high performance engines. The TOMEI products are always engineered with precision in mind to suit the user’s needs. So with this in mind careful choices in material selection is made with surface coating and other technologies. Then the pre-production products are put through an extensive testing program for checking durability, quality and performance. We spend time and money to help you save your valuable time and money.

PRODUCT INFO

| APPLICATION |

TYPE |

COMPATIBLE LIFT(mm) |

P/N |

CHF |

NOTES |

| R33RB25DE(T) |

A |

~8.80 |

13203R855 |

432.68(TAX inc 466) |

|

| B |

~10.25 |

163022 |

648.09(TAX inc 698.00) |

・With Intake side retainers

・For solid conversions |

FEATURE / SPEC

|

DIA METER |

FREE LENGTH(mm) |

SET LENGTH(mm) |

LIFT LENGTH(mm) |

COMPRESSED LENGTH(mm) |

SET LOAD(kgf) |

LIFT LOAD(kgf) |

MATERIAL |

PROCESS |

COLOR ID |

| A TYPE IN |

Φ3.80 |

36.2 |

30.6 |

21.6 |

19.0 |

23.9 |

62.4±5% |

SWOSC-V |

Nitride |

Green |

| A TYPE EX |

Φ3.90 |

41.0 |

34.4 |

25.6 |

24.0 |

25.6±7% |

72.1±7% |

SWOSC-VX |

Nitride |

Blue |

| B TYPE (IN/EX) |

Φ3.90 |

41.0 |

35.0 |

25.0 |

24.0 |

24.2±7% |

80.6±7% |

SWOSC-VX |

Nitride |

Blue |

■ Multi Coil Unequal Pitch Springs

By combining several steps of spring rates into the one spring and vibration frequency becomes amazingly high. This greatly minimizes resonance and the chances of surging.

■ Advanced Oil Tempered Chromium-silicone Alloy Steel Core

Oil tempered chromium-silicone alloy steel wire is used which is considered to be the best material for springs for performance applications and evolved it even further. Combined with a new optimized design, not only did we make it tougher, we also succeeded in suppressing valve jumps or bounce even when raising the engines speeds RPM limit.

■ Shot Peening

A process that strikes many small steel balls onto the surface of the spring at high speeds is made to enhance the surface of the spring to raise its fatigue limit. Although it has been carried out earlier during the manufacturing process.

■ Warm Setting

The process that is adding higher loads beyond the actual limits to the highly heated spring. This will modify its shape and keep it permanently fixed. We succeeded in securing the highest performance over a long period of time while preventing sagging.

■ Nitriding

The surface treatment method for making nitrogen permeates the spring and gives it large surface compression repulsion. This method was chosen to raise the fatigue limit to suit the demands or running high lift camshafts. The dangers of spring failure is greatly reduced with the 1.5 times increase in the springs fatigue limit with the combined use of Oil tempered chromium-silicone alloy steel wire and Nitriding. This is how our valve springs are suitable for use on extreme engine speed conditions of super-high revs exceeding 10,000 RPM which had not been previously possible with high lift camshafts.

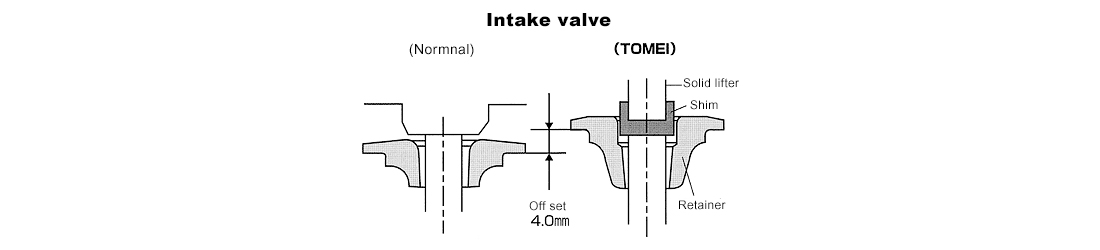

High lift camshaft could not be used for ECR33 RB25DET because NVCS oil pipe is running beneath the valve spring and it restricts the amount of the intake valve lift. Neither, could strengthen valve spring have been manufactured according to its construction.

Now, we developed RB25DET special intake valve retainer that enables corresponding to high lift camshaft by 10.25mm, by enlarging the amount of valve lift. Deceleration of the valve can be also secured by applying strengthen valve spring, which is required for the high lift camshaft and high rotation of the engine.

【Surging】

The Phenomenon which material of the valve spring resonance and causes the spring itself to vibrate violently.

【Jump】

The Phenomenon that the valve rallies to the cam surface instead of settled back. It happens when the valve cannot follow the camshaft rotation and lifted irregally.

【Bounce】

The Phenomenon that the valve is bouncing repeatedly from valve seat other than sticking to it when it is closing.

【Fatigue】

Breakage that occurs during the repeat operation of the spring. (The larger lift, the more possibilities to get fatigued)

【Sag】

The Phenomenon in which the load (free play) of a spring decreases while inuse. It is related to the maximum stress under operation and use time.

by Hanshin-Imports | Mar 19, 2019

PRODUCT INFO

| APPLICATION |

IN/EX |

P/N |

CHF |

NOTES |

RB26DETT

RB25DE(T)

RB20DE(T) |

IN |

152009 |

178.27(TAX inc 192.00) |

|

| EX |

152010 |

178.27(TAX inc 192.00) |

|

FEATURE / SPEC

| TYPE |

MATERIAL |

WEIGHT |

| PULLEY |

GEAR |

| SLIDE |

DURALUMIN |

DURALUMIN |

340g |

■ Super Lightweight Duralumin

The Duralumin alloy was chosen for it’s super light weight properties. So our product is made from 100% Duralumin.

■ SUPERIOR ACCURACY

Both the pulley and the gear sections were manufactured from special precision methods.

This helps secure the set position from the transmission drive to the timing belt.

■ SUPERIOR DURABILITY

Highly durable in contact areas with the timing belt has been greatly enhanced by giving the industry’s first product to have deep anodized colouring applied to the surface of the pulley.

It is suited for Drag Racing Cars that are well over 1000 HP and rev well past the 10,000 RPM mark. There are also no signs of the colour coming off.

■ UNIQUE DESIGN THAT STANDS OUT

Every bit of the pure Duralumin was processed with the deep anodized colour.

With the functional design.

■ USER FRIENDLY ADJUSTABLE SCALE

Great consideration was taken in making a simple and easy to follow adjustable scale for anyone to understand.

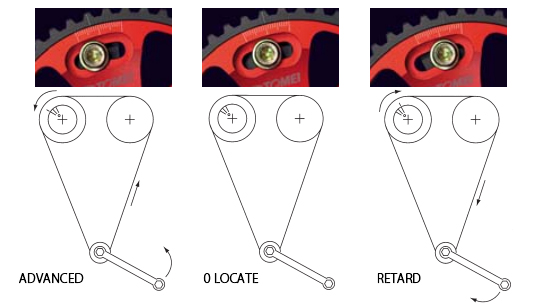

SLIDING ADJUSTER

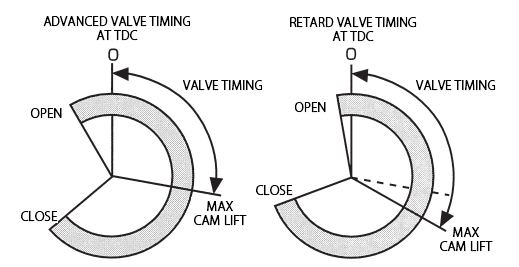

The simple graph makes it easy to change the engines characteristics with the simple sliding adjustments of the Cam Gear. If the intake valve timing is advanced (i.e. 120° to 110°) then performance gains are achieved at low RPM. If the intake valve timing is retarded (i.e. 110° to 120°) then performance gains are achieved at high RPM. Camshafts with no dowel pin attached will require you to check the timing adjustments with a dial gauge and scale board.

EASY VALVE TIMING ADJUSTMENTS WITH PONCAM

The Poncams valve timing has been preset at 110°. This Valve Timing has been calculated as the best setting for both performance and drivability. You can adjust the engines performance by making adjustments with the cam Gear carefully. This easy adjustable system is a great advantage over other conventional designs.

![]()

![Tomei Kit Poncam RB25DE[T]](https://hanshin-imports.ch/wp-content/uploads/2020/12/products-4009.jpg)