by Hanshin-Imports | Mar 19, 2019

PRODUCT INFO

| APPLICATION |

BORE |

THICKNESS |

P/N |

CHF |

MATERIAL |

STRUCTURE |

| RB20DE(T) |

φ87.0 |

1.2mm |

1312870121 |

336.12HT(Tax inc 362.00) |

Metal |

Super Grommet |

| 1.5mm |

1312870151 |

| 1.8mm |

1312870181 |

| φ88.0 |

1.2mm |

11044R904G |

| 1.5mm |

11044R905G |

FEATURE / SPEC

■ SUPER GROMMET DESIGN

The sealing performance has been improved considerably with the super grommet,to suit these engines and has been proven to brliver excellent relibility.

|

SUPER GROMMET TYPE

The dual sealing method of the bead structure & metal grommet, provides maximum sealing for the coolant, oil & gases around the bore circumference. |

■ Heat Conductivity & The Strength of Stainless Steel

Stainless steel was chosen to be the material of choice to make the Metal Gaskets with because of the heat conductivity efficiency of the stainless steel material to evenly distribute the heat and aid with cooling. This will greatly improve reliability and reduce the chances of problems.

The natural high tensile qualities of Stainless Steel greatly helps with increasing the joint ridged of the cylinder head with the cylinder block. This helps minimize the engine from warping when under severe stress loads that performance engines go through when running high power applications. The result is improved durability and added power gains.

■ ABOUT MARKING

All our metal head gaskets are laser marked with Models, Bores, Thickness, and TOMEI POWERED INC. company name.

Since there are similar/counterfeit goods on market, please make sure logos on Gasket. |

|

●TURBO

| GASKETφ87.0 |

PSITON STDφ86.0 |

PSITON TOMEI φ87.0 |

| 1.2mm |

Approx.9.0 |

Approx.8.5 |

| 1.5mm |

Approx.8.7 |

Approx.8.2 |

| 1.8mm |

Approx.8.5 |

Approx.8.0 |

| 2.0mm |

Approx.8.3 |

Approx.7.9 |

| GASKETφ88.0 |

PSITON STDφ86.0 |

PSITON TOMEI φ87.0 |

| 1.2mm |

Approx.9.0 |

Approx.8.5 |

| 1.5mm |

Approx.8.7 |

Approx.8.2 |

| 1.8mm |

Approx.8.4 |

Approx.8.0 |

| 2.0mm |

Approx.8.3 |

Approx.7.9 |

●TURBO 2.8L KIT

| GASKETφ87.0 |

PSITON TOMEI 2.8L φ86.5 |

PSITON(VALVE RECESSED) TOMEI 2.8Lφ86.5 |

| 1.2mm |

Approx.9.0 |

Approx.8.8 |

| 1.5mm |

Approx.8.8 |

Approx.8.6 |

| 1.8mm |

Approx.8.6 |

Approx.8.3 |

| 2.0mm |

Approx.8.4 |

Approx.8.2 |

| GASKETφ87.0 |

PSITON TOMEI 2.8L φ87.0 |

PSITON(VALVE RECESSED) TOMEI 2.8Lφ87.0 |

| 1.2mm |

Approx.9.1 |

Approx.8.9 |

| 1.5mm |

Approx.8.9 |

Approx.8.6 |

| 1.8mm |

Approx.8.6 |

Approx.8.4 |

| 2.0mm |

Approx.8.5 |

Approx.8.3 |

| GASKETφ87.0 |

PSITON TOMEI 2.8L φ87.5 |

PSITON(VALVE RECESSED) TOMEI 2.8Lφ87.5 |

| 1.2mm |

Approx.9.2 |

Approx.8.9 |

| 1.5mm |

Approx.8.9 |

Approx.8.6 |

| 1.8mm |

Approx.8.7 |

Approx.8.4 |

| 2.0mm |

Approx.8.6 |

Approx.8.3 |

●NA

| GASKETφ87.0 |

PSITON STD φ86.0 |

| 1.0mm |

Approx.10.0 |

| 1.2mm |

Approx.9.7 |

| 1.5mm |

Approx.9.4 |

| 1.8mm |

Approx.9.2 |

Values of the sample compression ratios are calculated out based on the factory spec data.

Adjustment of the compression ratio must be based on the measurement of the actual engine.

by Hanshin-Imports | Jan 28, 2019

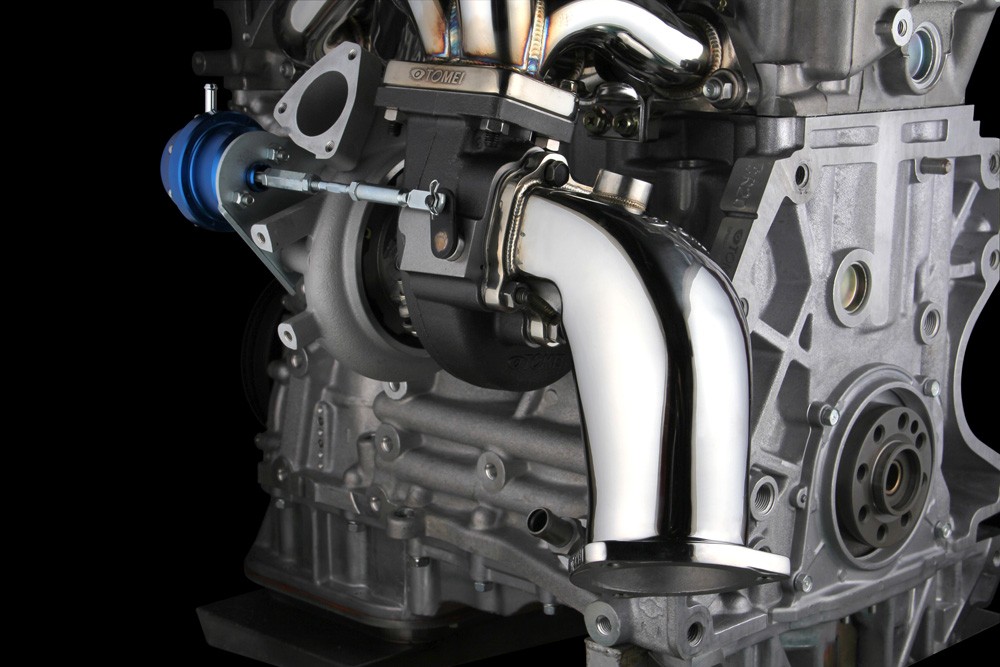

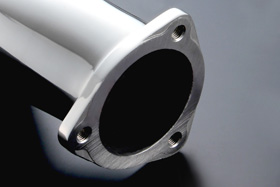

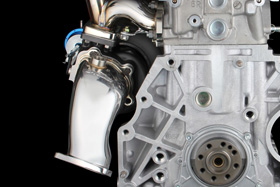

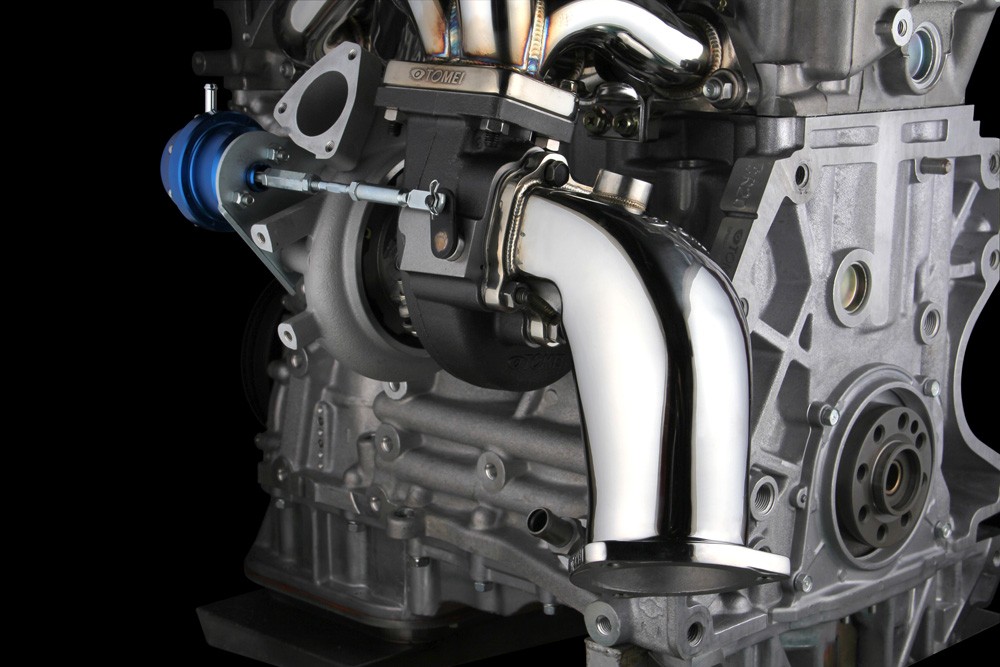

JOINT PIPE KIT EXPREME FA20 ZN6/ZC6

|

|

|

|

|

Larger diameter for improved exhaust efficiency and precision clearance design

|

| The stock joint pipe is not only narrow, it also has flattened sections which severely limits the performance gains from fitting a high efficiency manifold. However, our new pipe has its sections welded together to maintain a wide Φ60.5 diameter throughout with additional weld beads on the inside for rigidity. |

|

|

|

|

|

| JOINT PIPE (1) |

|

| GASKET (2) |

|

| FLANGE BOLT (1) |

|

|

| STUD BOLT (2) |

|

| FLANGE NUT (4) |

|

|

| BOLT SMOOTH PASTE (1) |

|

|

|

|

| APPLICATION |

PART NUMBER |

| TOYOTA 86 |

P/N 431104 |

| SCION FR-S |

| SUBARU BRZ |

|

|

|

MSRP 359 (CHF)

|

| Designed for Competition Use only |

|

|

| TEST RESULTS WHEN FITTED WITH A TOMEI EXHAUST MANIFOLD |

|

|

|

| SPECIFICATIONS COMPARISON VS STOCK |

|

|

|

|

|

| EXHAUST MANIFOLD SIDE |

MUFFLER SIDE |

|

|

|

MATERIAL

|

PIPE DIAMETER

(Φ)

|

PIPE

THICKNESS

(mm) |

FLANGE

THICKNESS

(mm) |

WEIGHT

(kg / lbs) |

|

STOCK

|

–

|

54.0

|

1.5 |

10.0 |

2.0 / 4.4 |

|

TOMEI

|

SUS304

|

60.5

|

1.5 |

11.0 |

1.5 / 3.3 |

|

|

|

| OTHER FEATURES |

|

|

Even with the stock setup, handling around the joint pipe pass-through is challenging given the limited clearance. However, our dedicated engineers have achieved precision clearance even with the wider pipe. |

|

|

|

| Other exhaust related parts released together for the 86/FR-S/BRZ |

|

|

|

| EQUAL LENGTH EXHAUST MANIFOLD |

UNEQUAL LENGTH EXHAUST MANIFOLD |

|

|

by Hanshin-Imports | Jan 26, 2019

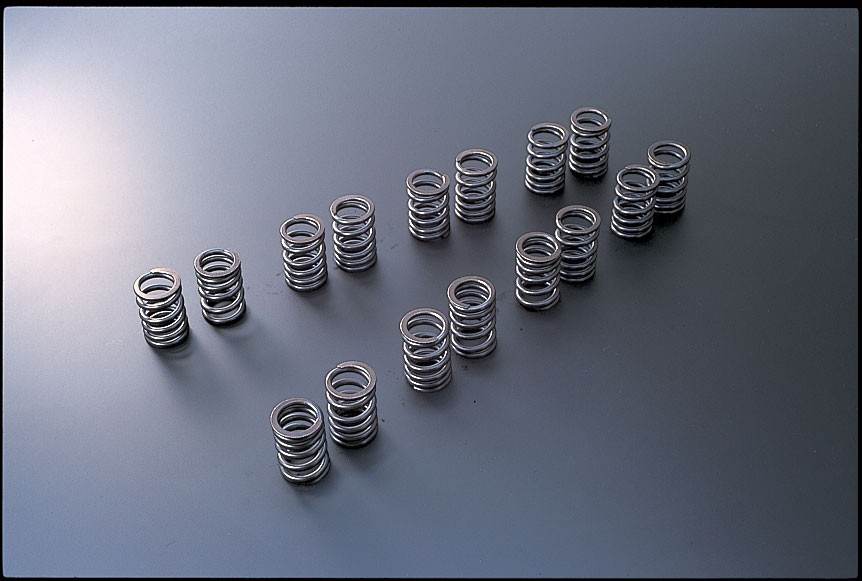

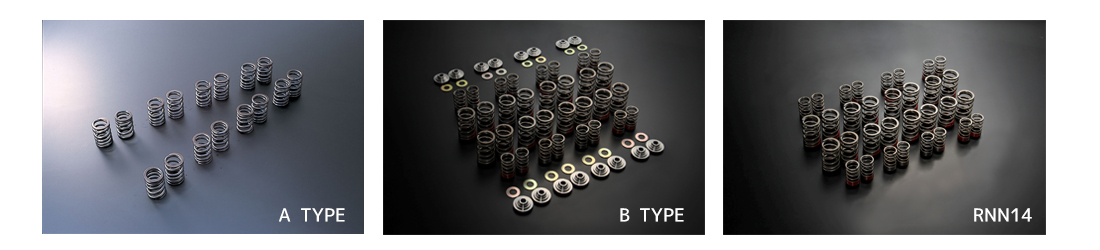

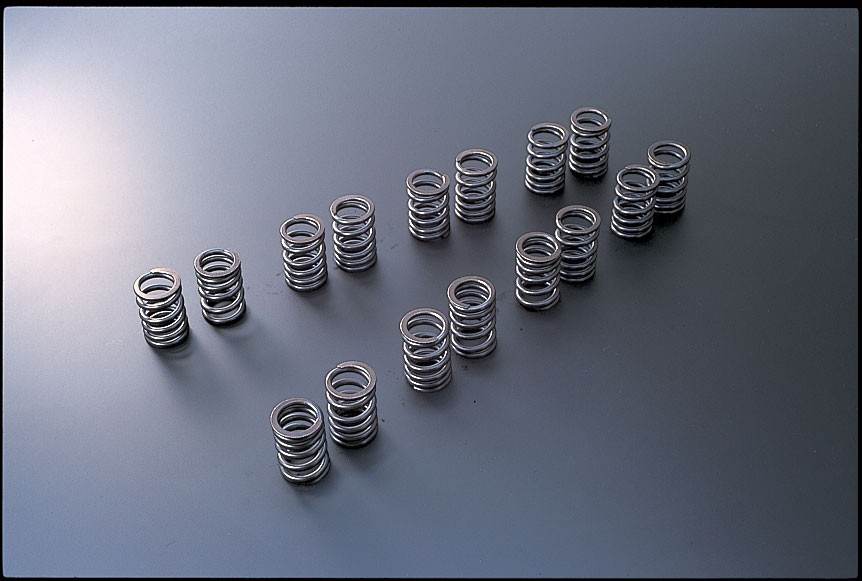

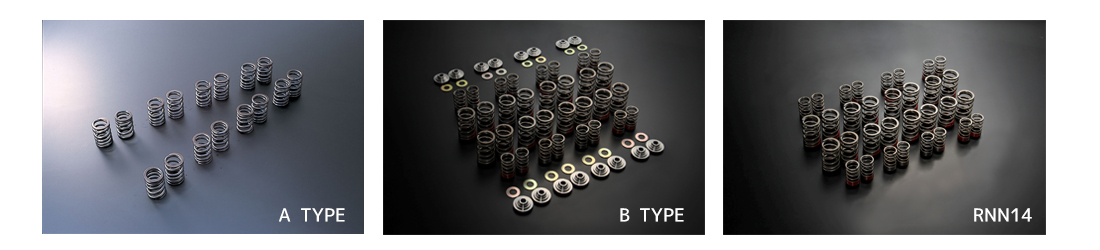

High quality designed springs is required to transfer the exact movement of the camshaft to the valves at high engine speeds on high performance engines. The TOMEI products are always engineered with precision in mind to suit the user’s needs. So with this in mind careful choices in material selection is made with surface coating and other technologies. Then the pre-production products are put through an extensive testing program for checking durability, quality and performance. We spend time and money to help you save your valuable time and money.

PRODUCT INFO

| APPLICATION |

TYPE |

COMPATIBLE LIFT(mm) |

P/N |

CHF |

NOTES |

| SR20DE(T) |

A |

~12.50 |

173004 |

259.-TTC |

|

| B |

~12.50 |

163055 |

931.- TTC |

Double springs and special titanium retainers With spring seats |

| RNN14 |

~12.50 |

13203R301 |

698.- TTC

|

Double Spring |

FEATURE / SPEC

| |

DIA METER |

FREE LENGTH(mm) |

SET LENGTH(mm) |

LIFT LENGTH(mm) |

COMPRESSED LENGTH(mm) |

SET LOAD(kgf) |

LIFT LOAD(kgf) |

MATERIAL |

PROCESS |

COLOR ID |

| A TYPE |

Φ4.00 |

48.0 |

40.0 |

27.5 |

26.5 |

25.6±7% |

81.6±7% |

SWOSC-VX |

Nitride |

Red |

| B TYPE |

INNER |

Φ2.50 |

35.2 |

32.2 |

19.7 |

18.7 |

3.4±8% |

23.4±8% |

SWOSC-VX |

Nitride |

Red |

| OUTER |

Φ4.00 |

48.0 |

40.0 |

27.5 |

26.5 |

25.6±7% |

81.6±7% |

SWOSC-VX |

Nitride |

Red |

| COMBINED |

|

|

|

|

|

29.0±8% |

105.0±8% |

|

|

|

| RNN14 |

INNER |

Φ2.30 |

43.3 |

31.0 |

19.0 |

17.5 |

9.0 |

24.0 |

SWOSC-V |

Nitride |

Nil |

| OUTER |

Φ3.80 |

46.4 |

38.0 |

26.0 |

24.4 |

20.0 |

60.0 |

SWOSC-V |

Nitride |

Nil |

| COMBINED |

|

|

|

|

|

29.0 |

84.0 |

|

|

|

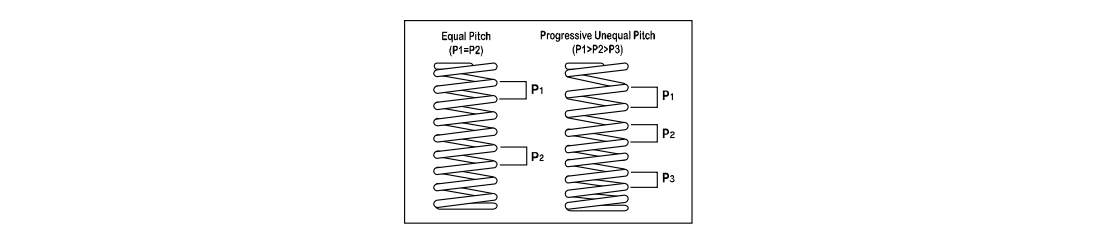

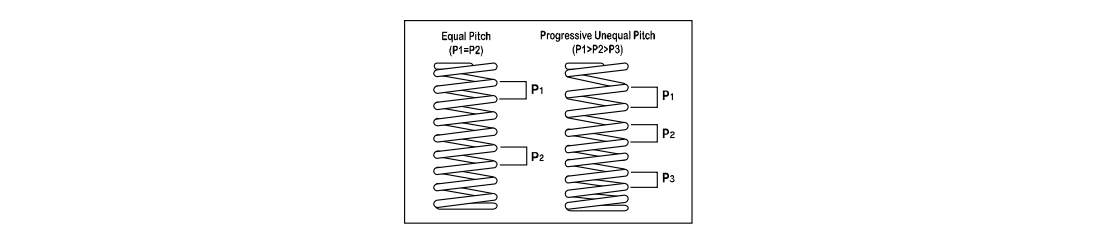

■ Multi Coil Unequal Pitch Springs

By combining several steps of spring rates into the one spring and vibration frequency becomes amazingly high. This greatly minimizes resonance and the chances of surging.

■ Advanced Oil Tempered Chromium-silicone Alloy Steel Core

Oil tempered chromium-silicone alloy steel wire is used which is considered to be the best material for springs for performance applications and evolved it even further. Combined with a new optimized design, not only did we make it tougher, we also succeeded in suppressing valve jumps or bounce even when raising the engines speeds RPM limit.

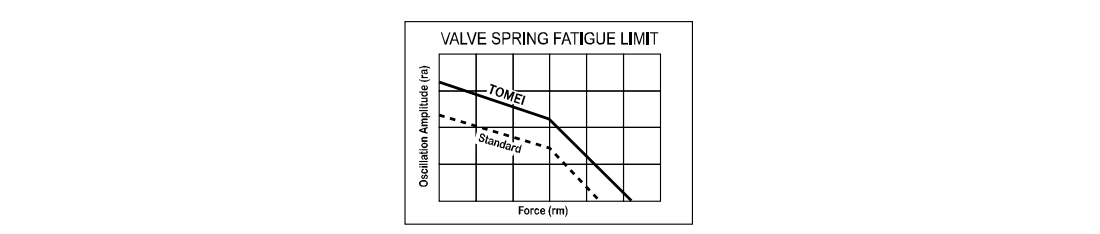

■ Shot Peening

A process that strikes many small steel balls onto the surface of the spring at high speeds is made to enhance the surface of the spring to raise its fatigue limit. Although it has been carried out earlier during the manufacturing process.

■ Warm Setting

The process that is adding higher loads beyond the actual limits to the highly heated spring. This will modify its shape and keep it permanently fixed. We succeeded in securing the highest performance over a long period of time while preventing sagging.

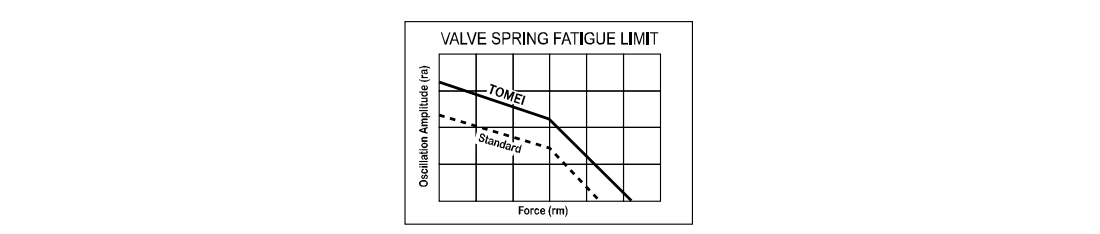

■ Nitriding

The surface treatment method for making nitrogen permeates the spring and gives it large surface compression repulsion. This method was chosen to raise the fatigue limit to suit the demands or running high lift camshafts. The dangers of spring failure is greatly reduced with the 1.5 times increase in the springs fatigue limit with the combined use of Oil tempered chromium-silicone alloy steel wire and Nitriding. This is how our valve springs are suitable for use on extreme engine speed conditions of super-high revs exceeding 10,000 RPM which had not been previously possible with high lift camshafts.

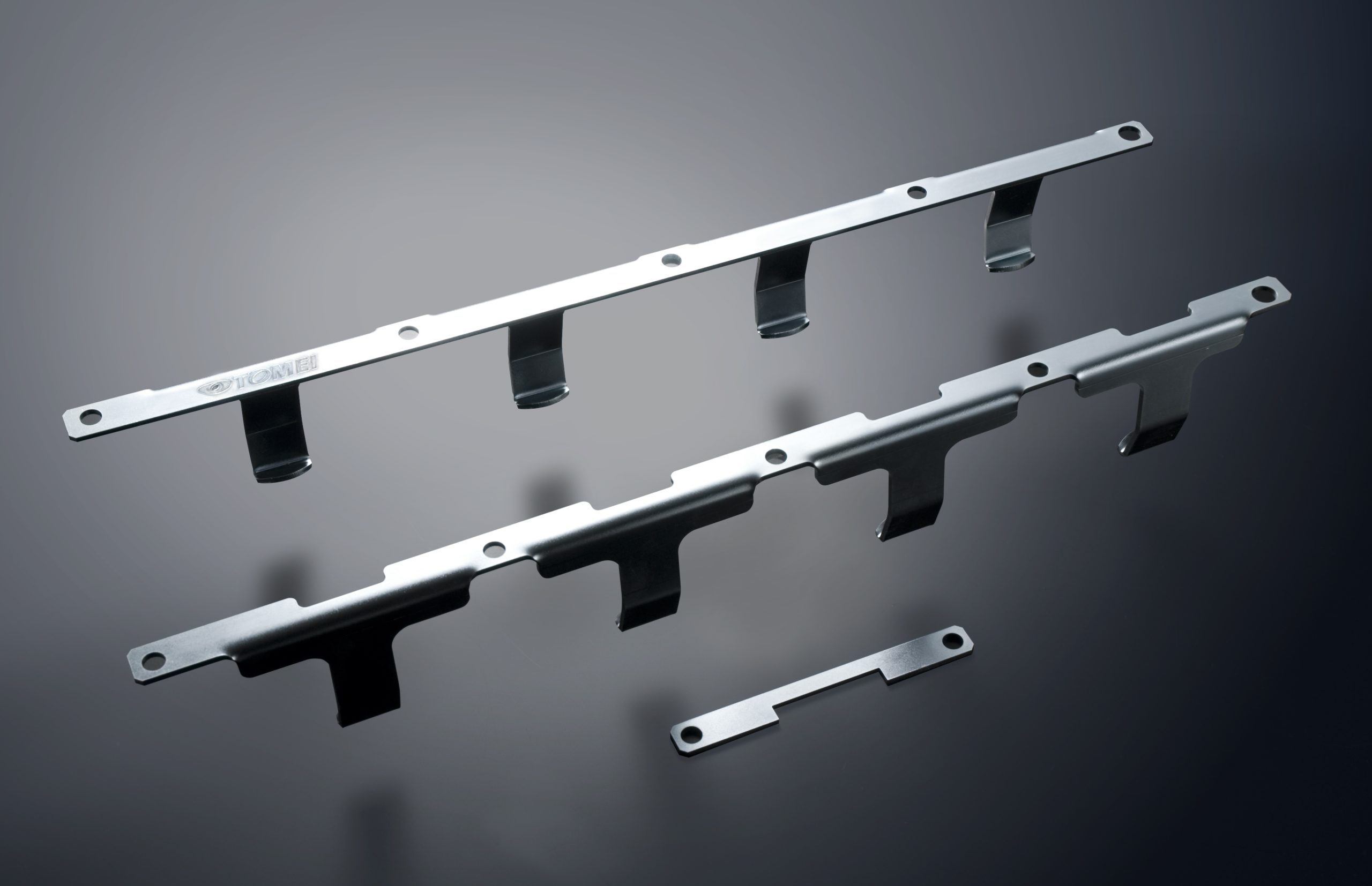

by Hanshin-Imports | Jan 25, 2019

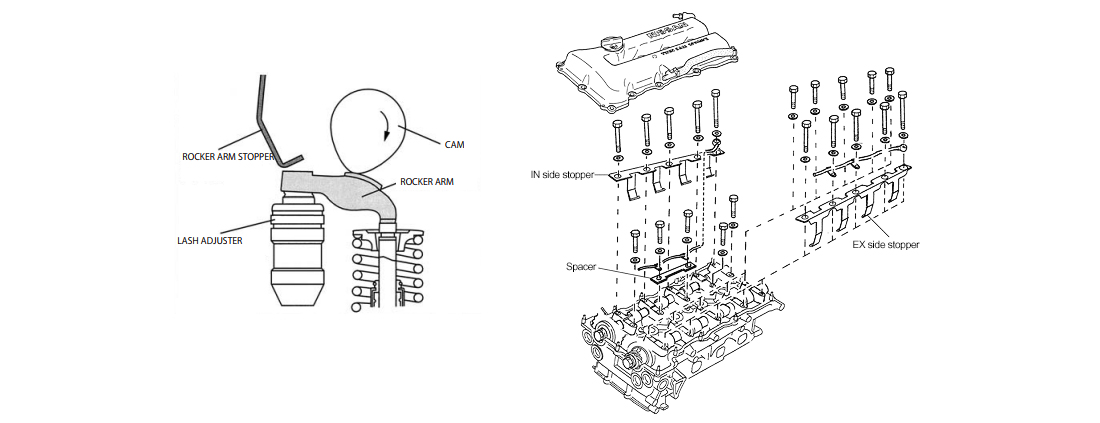

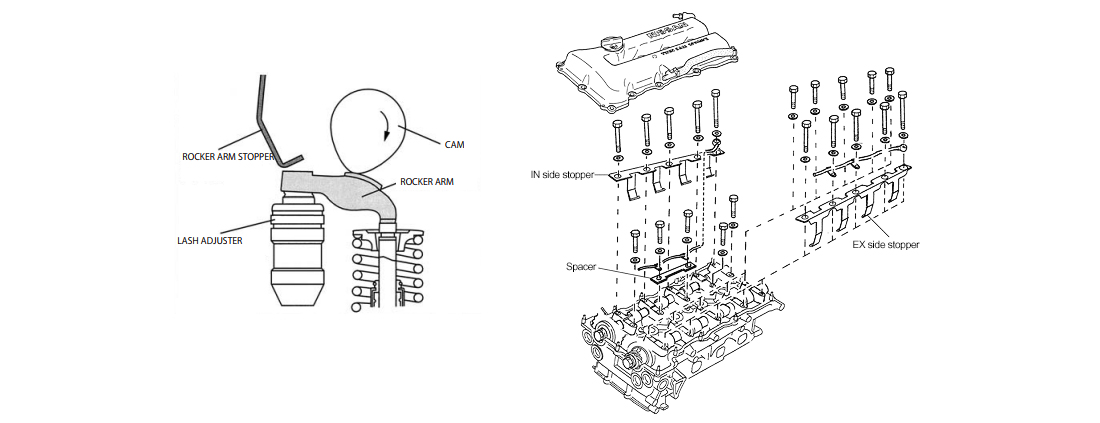

When over revving or miss-shifting the SR engine whilst at 7000 RPM and over during circuit runs or drag racing can sometimes cause the tappet side of the rocker arm to jump and rocker arm to come off. This Rocker Arm Stopper is a simple cost effective part which holds the lash adjuster side of Rocker Arm in place with a fixed clearance that prevents the rocker arm from disastrous results when the arm jumps and so will protect your engine from terminal damage.

PRODUCT INFO

| APPLICATION |

P/N |

JPY |

NOTES |

| SR20DE(T)

(R)PS13,S14,S15,P10 |

13220R300 |

¥6,000(Tax inc 6,480) |

・ The S14/15 Rocker Covers will need some additional work.

・Cannot be used with VVL.

・ Can be used with Solid Pivot conversions. |

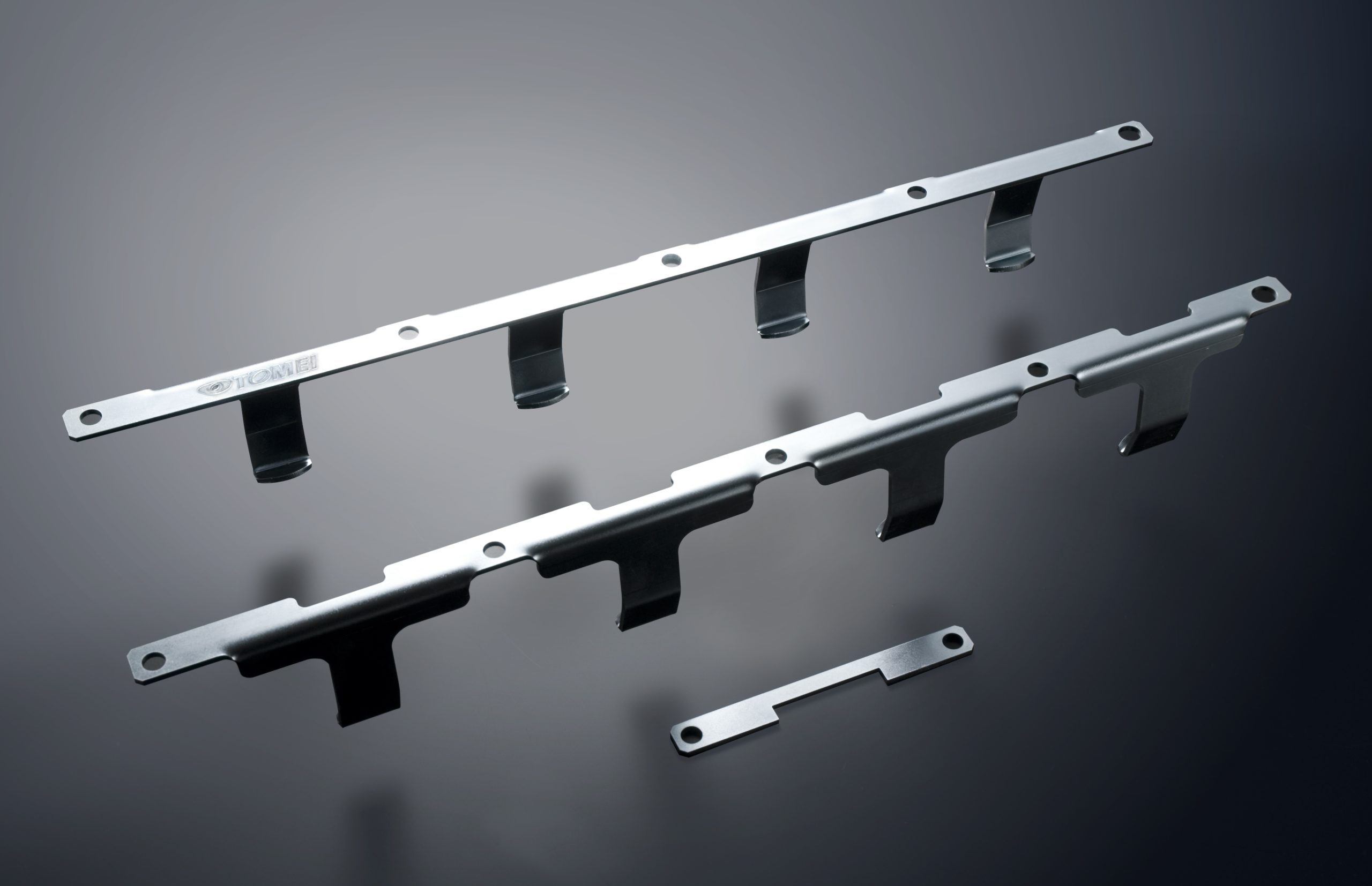

FEATURE / SPEC

| MATERIAL |

SPCC CHROME(steel)

|

| WEIGHT |

170g |

by Hanshin-Imports | Jan 25, 2019

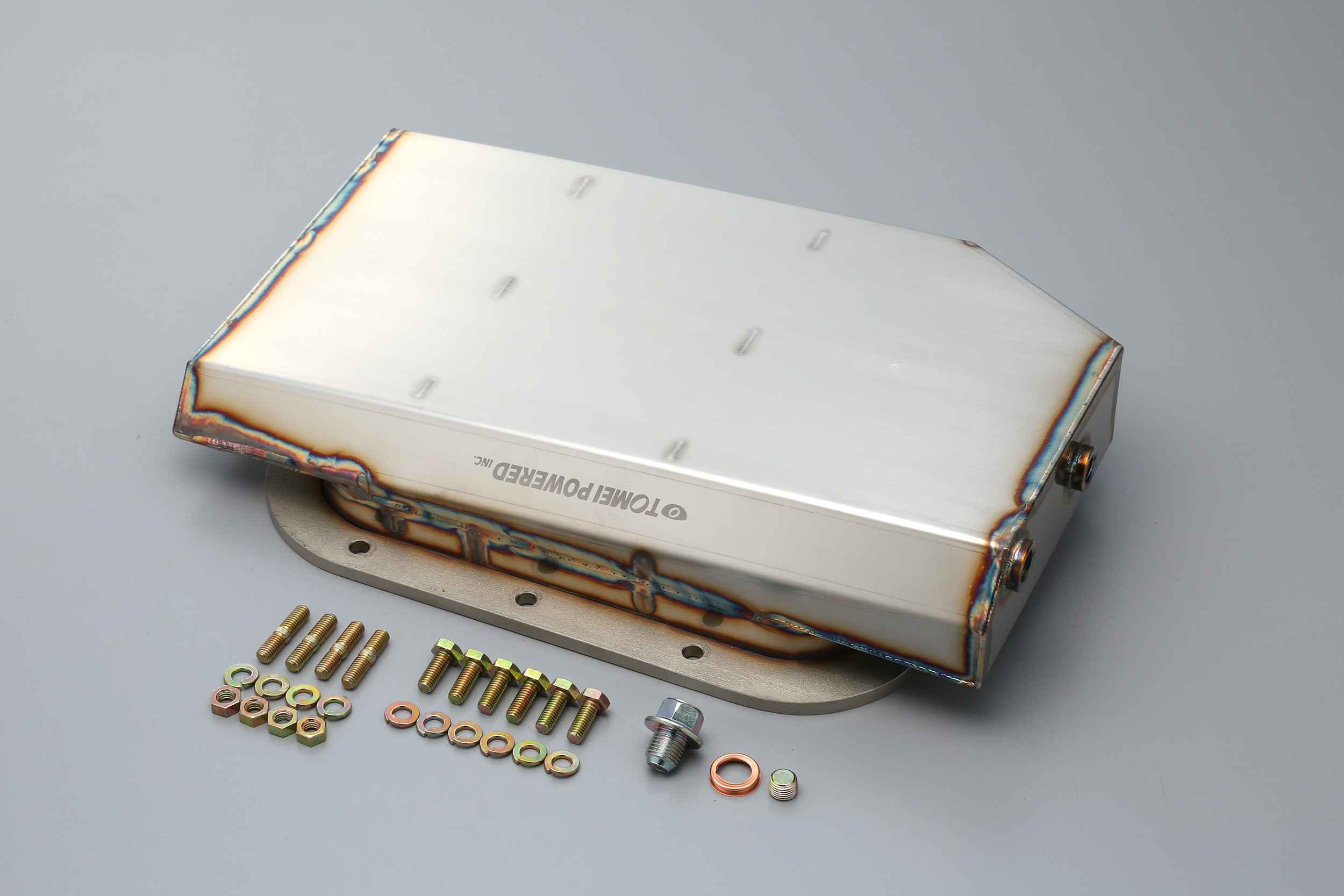

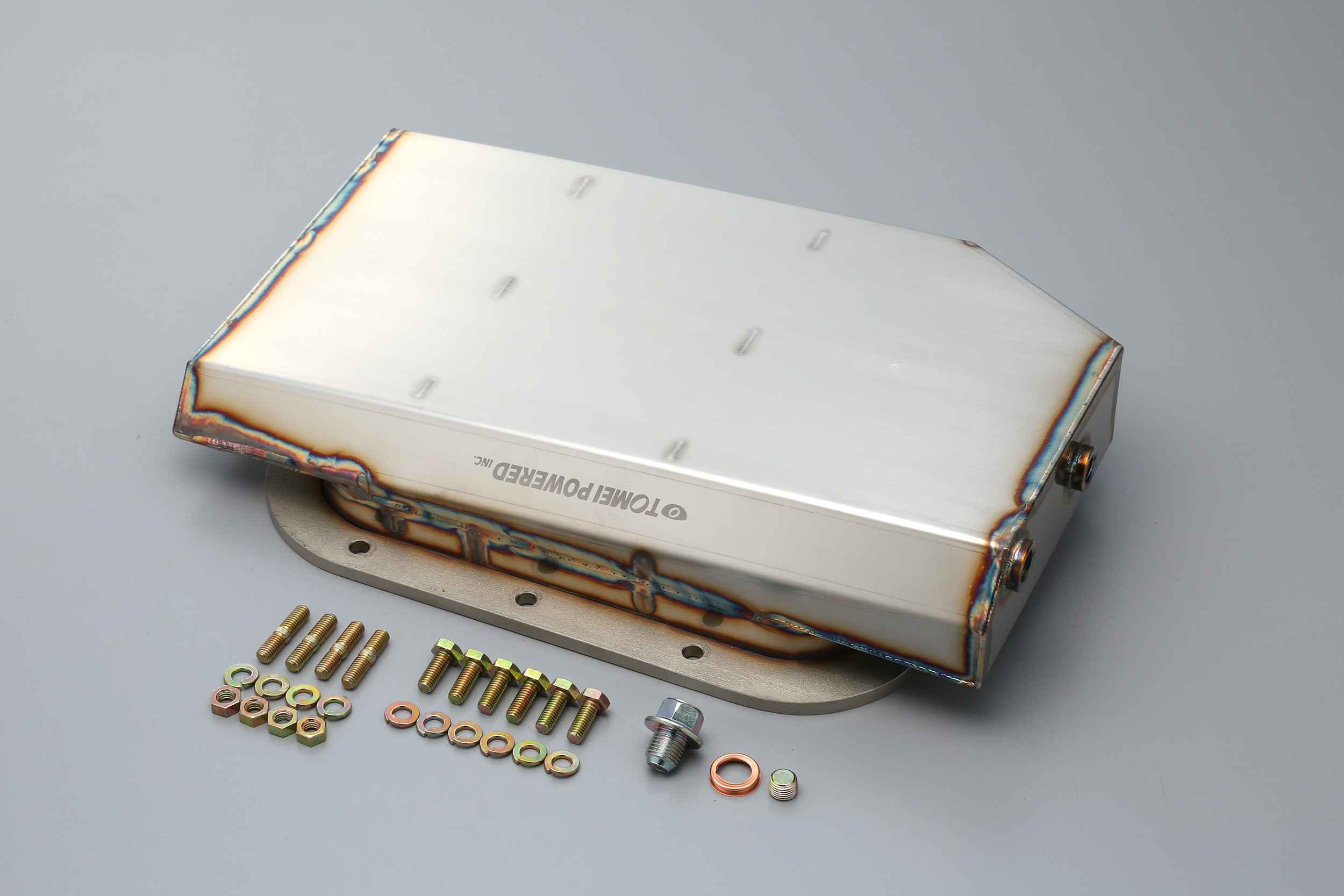

The oil in the sump will forced to the side walls of the oil pan during side G force loads during Drifting, Time Attack and Drag Racing use. These problems can escalate to serious oil starvation in the engine when there is inadequate oil in the sump for the oil pickup which can lead to engine failure.

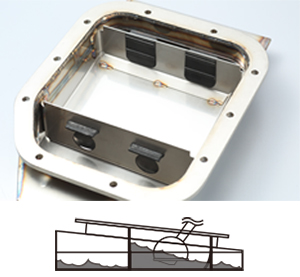

This oil pan increases the capacity with an extra 600cc without compromising the ground clearance so really low cars will not have any issues. With the internal design featuring 2 swing back doors which further aid with holding the oil in the center of the pan for the oil pickup point.

PRODUCT INFO

| APPLICATION |

ENGINE |

P/N |

JPY |

NOTES |

| (R)PS13/S14/S15 |

SR20DE(T) |

11111R520 |

410.- TTC |

・600cc Increased Capacity

・Has Oil Temp Sensor Attachment (PT1/8)

・Non compatible with N14 Pulsar engines. |

FEATURE / SPEC

|

BORN & BRED FROM AN N2 RACE SPEC SILVIA.

The Silvia N2 race car was powered by a Tomei 270HP NA engine which back in the day was named the “Ultimate SR20 Race Engine”.

The regulations prevented the use of a dry sump setup so under the extreme track conditions the standard wet sump setup had to be re-designed to cope with the requirements that the race engine needed. Road clearance was taken into account for the ultra low ride height of the car and even after all these years this oil pan is still popular with SR20 users. |

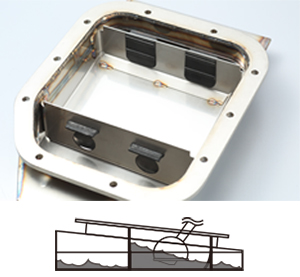

■ Designed for G-Forces

The 2 plates with the one way rubber valve made in the pan are specifically designed to keep the pickup submerged in oil at all times.

The stock oil pan was not designed for the serious performance so when the oil moves away from the pickup and then if any air gets sucked into the lines. Then that brief moment when no oil is supplied to the vital areas, metal contact is made and unwanted metal friction in sensitive areas which then leads to engine failure. |

|

■ High Strength & Accurate Welds,Maintain Road Clearance

Our highly accurate welding on pan with our famous strict standards to ensure no oil leaks with the high quality welds and as a direct bolt on product as you would expect.

Unlike the cast type oil pans this is made with stronger materials which will take a good hit and not crack like a cast based one would. Stronger and safer for your engine.

■ Optimum Oil Level

The extra 600cc was decided as it was found to be the best amount to suit for the required performance to suit the needs of the N2 race cars in the past. Still to this day this is still the best amount for Time Attack, Circuit use, Drift and Drag Racing. Designed to maintain an adequate level of oil for the pickup to supply the engine without compromising performance with unwanted friction on the spinning crankshaft or extra weight.

【OIL SPLASHING & WINDAGE】

The combination of the spinning crankshaft and G-forces will cause cavitations (oil bubbles) at higher engine speeds which leads to erratic oil pressures and reduced oil supply to the engine.

by Hanshin-Imports | Jan 23, 2019

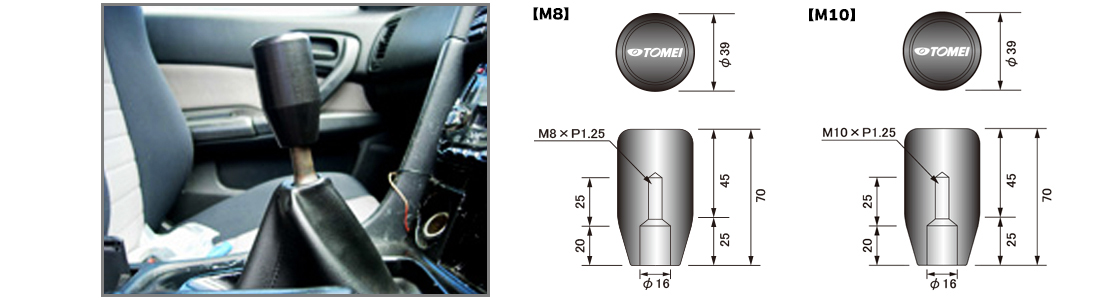

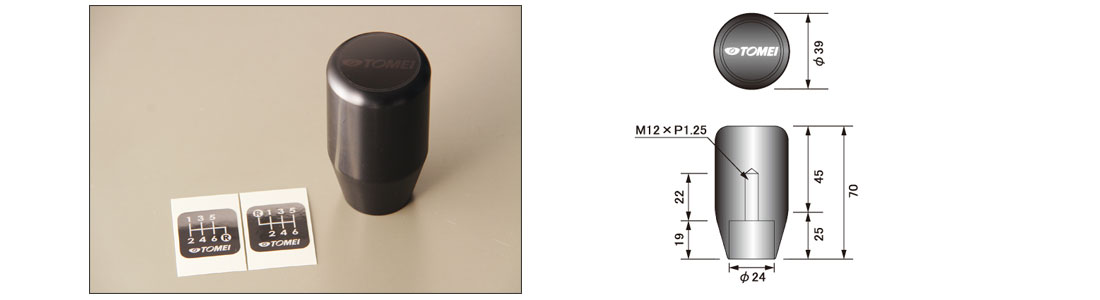

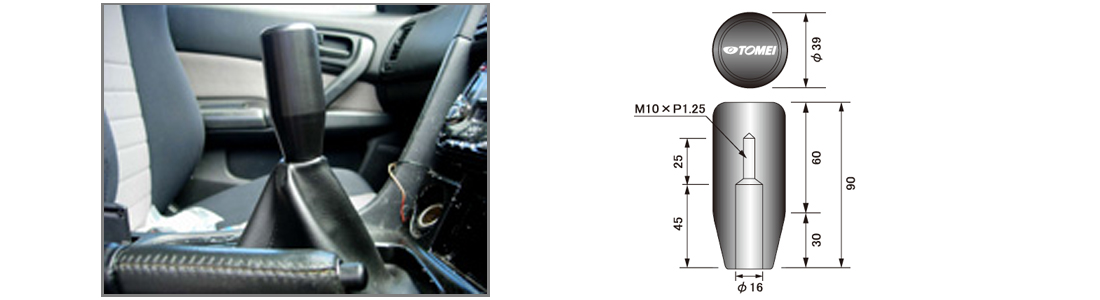

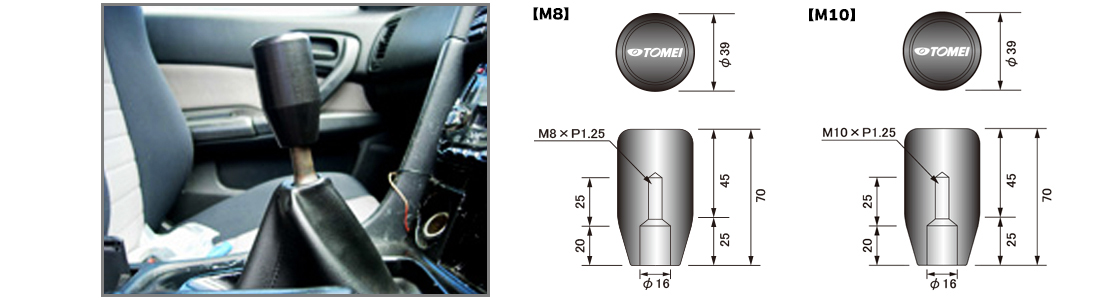

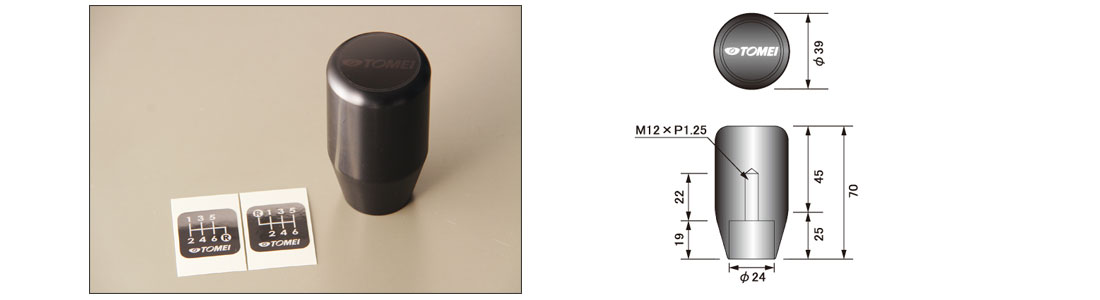

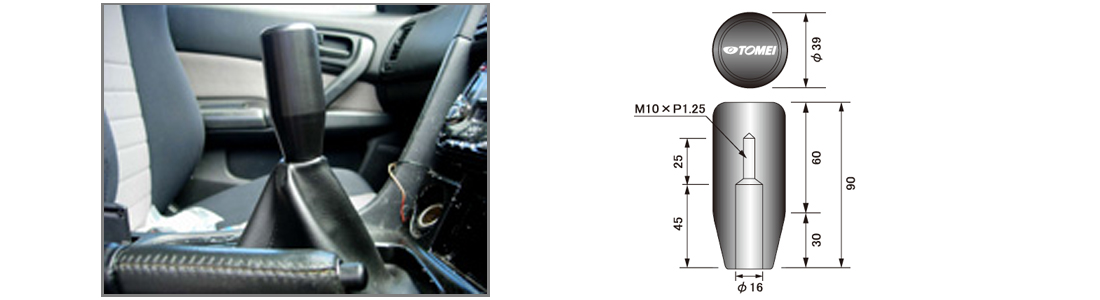

TOMEI SHIFT KNOB

PRODUCT INFO

| TYPE |

APPLICATION |

P/N |

CHF |

MATERIAL |

| SHORT |

M8 |

NISSAN |

763004 |

(Tax inc 45.-) |

DURACON |

| M10 |

NISSAN

MITSUBISHI

MAZDA |

32865S010S |

M12

※for 6th |

NISSAN

SUBARU

TOYOTA |

763003 |

| LONG |

M10 |

NISSAN

MITSUBISHI

MAZDA |

32865S010L |

※The difference between the short and long type is the bottom threaded section.

Please check the distance between the base of the screw thread to the top of the boot prior to purchasing.

These designs will not change your gear levers stroke distance.

※Please check your thread size, prior to making your purchase.

FEATURE / SPEC

■DURACON MATERIAL

A popular synthetic resin material that is often used for competition because of its heat resistance and high durability properties.

When used for a shift knob, the beautiful glossy surface finish is comfortable for anyone’s hands.

■SHORT M10

■SHORT M12

■LONG

by Hanshin-Imports | Jan 23, 2019

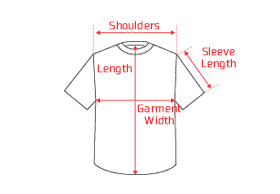

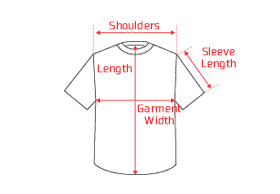

PRODUCT INFO

| PRODUCT |

COLOR |

SIZE |

P/N |

CHF |

MATERIAL |

| “Go for a ride” Hooded Parker |

Black |

S |

795084 |

55.71.-HT (Tax inc 60.-TTC) |

Cotton 35%

Polyester 65% |

| M |

795085 |

| L |

795086 |

| XL |

795087 |

| 2XL |

795088 |

| 3XL |

795089 |

FEATURE / SPEC

| SIZE |

LENGTH |

SHOULDERS |

GARMENT WIDTH |

SLEEVE LENGTH |

| S |

59 |

42 |

46 |

55 |

| M |

63 |

43 |

49 |

58 |

| L |

64 |

45 |

50 |

59 |

| XL |

65 |

48 |

51 |

64 |

| 2XL |

67 |

52 |

54 |

65 |

| 3XL |

69 |

57 |

59 |

66 |

by Hanshin-Imports | Jan 22, 2019

PRODUCT INFO

| PRODUCT |

COLOR |

SIZE |

P/N |

CHF |

MATERIAL |

| “Go for a ride” T-shirts |

Black |

S |

795057 |

32.49.-HT (Tax inc 35.- TTC) |

Cotton 100% |

| M |

795058 |

| L |

795059 |

| XL |

795060 |

| 2XL |

795061 |

| 3XL |

795062 |

FEATURE / SPEC

| SIZE |

LENGTH |

SHOULDERS |

GARMENT WIDTH |

SLEEVE LENGTH |

| S |

66 |

44 |

49 |

19 |

| M |

70 |

47 |

52 |

20 |

| L |

74 |

50 |

55 |

22 |

| XL |

78 |

53 |

58 |

24 |

| 2XL |

82 |

56 |

61 |

26 |

| 3XL |

84 |

59 |

64 |

26 |

by Hanshin-Imports | Oct 11, 2018

| FOR THE PRO-TUNER |

| ■Designed for solid lash adjusters |

| ■High power/rpm compatible |

| ■Works great with a variety of setups |

| ■Unleashes full potential with a professional tune |

|

●LASH PROCAM

| ANGLE |

LIFT (mm)

|

IN/EX

|

N /P

|

CHF

|

APPLICATION

|

NOTE 2

|

|

256°

|

11.50

|

IN

|

143E256115

|

296.19.-

(TTC 319.-)

|

PS13

|

PONCAM

(same item)

|

|

143G256115

|

S14,S15(NVCS compatible)

|

|

EX

|

1439256115

|

PS13,S14,S15

|

|

260°

|

12.00

|

IN

|

1431260120

|

PS13

|

|

|

143G260120

|

S14,S15(NVCS compatible)

|

|

|

EX

|

1432260120

|

PS13,S14,S15

|

|

|

270°

|

12.50

|

IN

|

1431270125

|

PS13

|

|

|

143G270125

|

S14,S15(NVCS compatible)

|

|

|

EX

|

1432270125

|

PS13,S14,S15

|

|

|

●SOLIDE PROCAM

|

ANGLE

|

LIFT(mm)

|

IN/EX

|

N / P

|

CHF

|

APPLICATION

|

NOTE 2

|

|

260°

|

12.00

|

IN

|

1435260120

|

296.19.-

(TTC 319.-)

|

PS13,RNN14

|

|

|

1433260120

|

S14,S15(NVCS compatible)

|

|

|

EX

|

1436260120

|

PS13,S14,S15

|

|

|

143K260120

|

RNN14

|

|

|

270°

|

12.50

|

IN

|

1435270125

|

PS13,RNN14

|

|

|

1433270125

|

S14,S15(NVCS compatible)

|

|

|

EX

|

1436270125

|

PS13,S14,S15

|

|

|

143K270125

|

RNN14

|

|

|

280°

|

12.50

|

IN

|

1435280125

|

PS13,RNN14

|

|

|

1433280125

|

S14,S15(NVCS compatible)

|

|

|

EX

|

1436280125

|

PS13,S14,S15

|

|

|

143K280125

|

RNN14

|

|

|

|

SPEC |

|

TYPE

|

ANGLE |

MAX

CAM

LIFT

|

IN/EX

|

MAXIMUM

VALVE

LIFT

|

|

INITIAL

SETTING VALUE

CENTER ANGLE

(DEGREE)

|

BASE

CIRCLE

|

REMARKS

|

|

RUSH

|

256

|

7.42

|

IN

|

11.50

|

–

|

110

|

ø32

|

|

|

120

|

NVCS COMPATIBLE

|

|

EX

|

–

|

115

|

|

|

260

|

7.70

|

IN

|

12.00

|

–

|

110

|

|

|

120

|

NVCS COMPATIBLE

|

|

EX

|

–

|

115

|

|

|

270

|

8.00

|

IN

|

12.50

|

–

|

110

|

|

|

120

|

NVCS COMPATIBLE

|

|

EX

|

–

|

115

|

|

|

|

260

|

7.88

|

IN

|

12.00

|

0.15

|

110

|

|

|

120

|

NVCS COMPATIBLE

|

|

EX

|

115

|

|

|

270

|

8.17

|

IN

|

12.50

|

110

|

|

|

120

|

NVCS COMPATIBLE

|

|

EX

|

115

|

|

|

280

|

8.17

|

IN

|

12.50

|

110

|

|

|

120

|

NVCS COMPATIBLE

|

|

EX

|

115

|

|

|

by Hanshin-Imports | Oct 11, 2018

by Hanshin-Imports | Oct 11, 2018

|

| SR20DET EXPREME EXHAUST MANIFOLD |

|

|

|

|

|

| |

|

KIT CONTENTS

|

| ■ |

EXHAUST MANIFOLD BODY |

| ■ |

GASKET |

| ■ |

MECLA COVER

|

| ■ |

EXPRIME BAND |

| ■ |

COMPLETE SET OF BOLTS |

| ■ |

BOLT SMOOTH PASTE

|

| ■ |

STICKER |

| ■ |

INSTRUCTION MANUAL |

|

|

|

|

|

|

|

|

|

|

| |

1.Acquire outstanding turbine response

|

Acquire outstanding turbone response by adopting a short pipe layout

|

|

| ■ |

2.Prevent excessive rise in exhaust pressure even at high rotation and obtain ideal exhaust efficiency

|

|

|

3.Equipped with support stay

|

|

By equipping the support stay, there is no worry in terms of strength |

|

|

|

|

|

|

| ■EXPREME Exhaust System for SR20DET |

| Car |

Engine |

N/P |

|

| (R)PS13 |

SR20DET |

193086 |

|

| S14 |

| S15 |

|

|

|

|

|

|

by Hanshin-Imports | Oct 11, 2018

Nissan Silvia/180SX

(R)PS13

S14/S15 |

SR20DET |

555cc |

4 |

16600R310 N/P |

CHF 713.09.- (Tax inc 768.00) |

195012 |

|

| 740cc |

193023 N/P |

CHF 713.09.-(Tax inc 768.00) |

195016 |

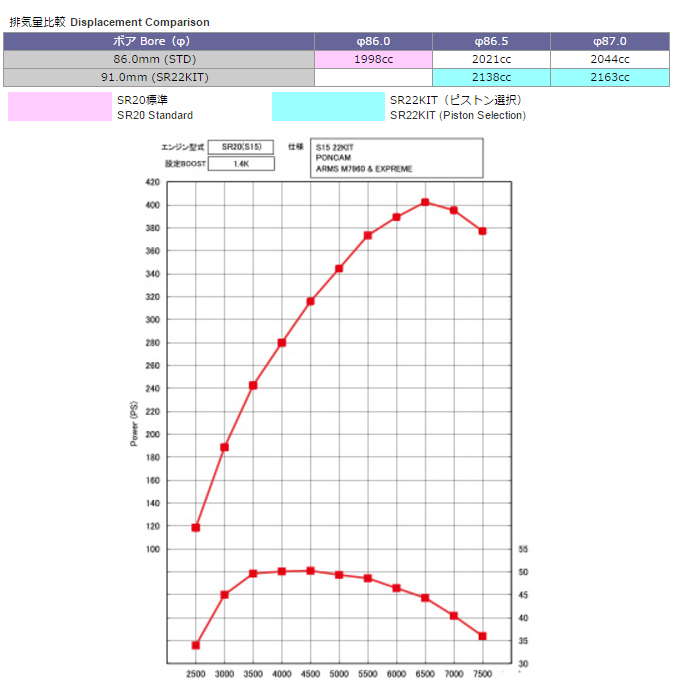

by Hanshin-Imports | Oct 10, 2018

|

|

TYPE

|

APPLICATION

|

ANGLE (IN)

|

ANGLE (EX)

|

LIFT (IN)

|

LIFT (EX)

|

N / P

|

CHF

|

|

R

|

[R]PS13

|

256°

|

256°

|

11.50

|

11.50

|

143043

|

592.38.-

(TTC 638.-)

|

|

S14,S15

|

143044

|

|

|

by Hanshin-Imports | Oct 9, 2018

PRODUCT INFO

| APPLICATION |

BORE |

P/N |

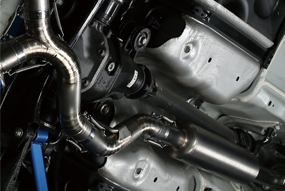

CHF |

NOTES |

(R)PS13

S14

S15 |

φ86.5 |

221030 |

3416.89.-

(Tax inc 3680.-) |

|

| φ87.0 |

221031 |

【With Conrod Bearings Bundle Pack】

| APPLICATION |

BORE |

P/N |

CHF |

NOTES |

(R)PS13

S14 |

φ86.5 |

250005 |

3662.02.-

(Tax inc 3944.-) |

|

| φ87.0 |

250006 |

* The conrod bearing option kit is supplied with the conrod bearings for the 1 engine application.

FEATURE / SPEC

PISTON

Bore

(Φ) |

Pin Dia

(Φ) |

Length

(mm) |

Recess |

Comp.Height

(mm) |

PistonCrownVolume

(cc) |

Weight

(g) |

Pin weight

(g) |

Total weight

(g) |

| 86.5 |

22.0 |

60 |

× |

29.5 |

18.0 |

323 |

113 |

436 |

| 87.0 |

× |

18.0 |

329 |

442 |

| Top ring B×T(mm) |

Second ring B×T(mm) |

Oil ring B×T(mm) |

| 1.2×3.1 |

1.2×3.9 |

2.5×3.1 |

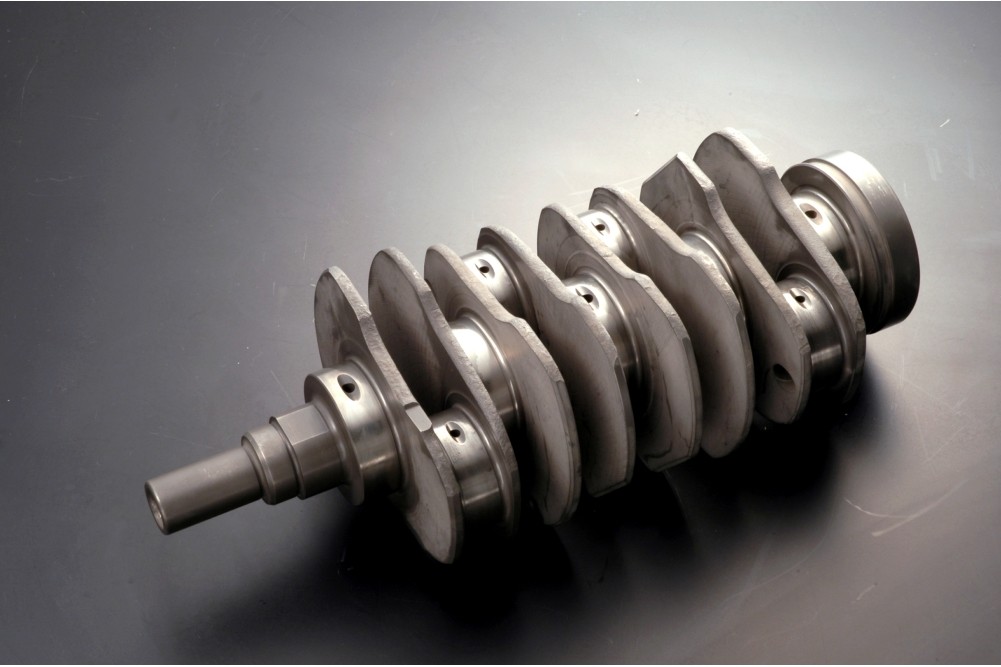

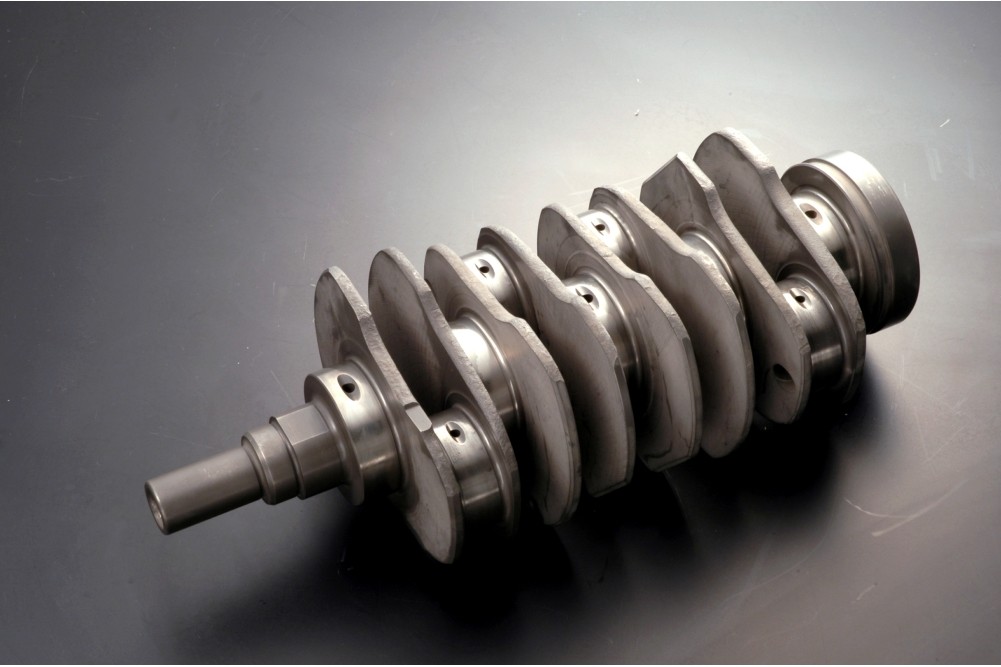

CRANKSHAFT

| Stroke (mm) |

Weight (kg) |

STD Stroke (mm) |

| 91.0 |

18.0 |

86.0 |

CONNECTING ROD

| Conrod |

Conrod Bolt |

Conrod Bearing |

Material |

Length

(mm) |

L.Diam×Length

(mm) |

S.Diam×Length

(mm) |

Bolt Size |

Height Under Neck

(mm) |

Inner Circum

(mm) |

Bearing Width

(mm) |

| 136.3 |

φ51×22.8 |

φ22×22.8 |

3/8-24 |

40 |

48 |

17.0 |

SNCM439 |

KIT WITH BEARINGS INCLUDED

Tomei has made an option to include their Competition Bearing Series product with our kits. All the engine internals are brought to static temperature (20 degrees Celcius) and blueprinted with 0.040~0.060mm clearance bearings.

This eliminates the measuring and blueprinting process for the customer, so the kit can be installed with less hassle.

by Hanshin-Imports | Sep 19, 2018

|

| ■ STRENGTH & PRECISION |

|

|

|

Product

|

Part No.

|

MSRP

|

|

FORGED FULL COUNTER

CRANKSHAFT

|

121045

|

$1,790.00

(USD)

|

|

|

|

STROKE

(mm)

|

WEIGHT

(kg)

|

STANDARD

STROKE (mm)

|

STANDARD

WEIGHT (kg)

|

MATERIAL

|

|

83

|

9.2

|

79

|

9.4

|

SNCM439

|

|

| |

|

| ■ BALANCED FULL COUNTERWEIGHT |

|

|

|

| ■ LIGHT & MINIMAL RESISTACE TYPE. |

|

|

|

| EJ26KIT FORGED FULL COUNTER CRANKSHAFT |

|

|

|

| ■ STRENGTH & PRECISION |

|

|

|

Product

|

Part No.

|

MSRP

|

|

FORGED FULL COUNTER

CRANKSHAFT

|

121045

|

2490.00.-

(CHF)

|

|

|

|

STROKE

(mm)

|

WEIGHT

(kg)

|

STANDARD

STROKE (mm)

|

STANDARD

WEIGHT (kg)

|

MATERIAL

|

|

83

|

9.2

|

79

|

9.4

|

SNCM439

|

|

| |

|

| ■ BALANCED FULL COUNTERWEIGHT |

|

|

|

| ■ LIGHT & MINIMAL RESISTACE TYPE. |

|

|

|

| EJ26KIT FORGED FULL COUNTER CRANKSHAFT |

|

|

by Hanshin-Imports | Sep 19, 2018

HEAD GASKET for EJ25

PRODUCT INFO

| APPLICATION |

BORE |

THICKNESS |

P/N |

CHF |

MATERIAL |

STRUCTURE |

NOTES |

EJ255 06-08 WRX

EJ257 WRX STI 04- |

φ101.2 |

0.7mm |

1361101071 |

348.-(Tax inc 375.-TTC) |

Metal |

Super Grommet |

2p/Set |

| 1.0mm |

1361101101 |

| 1.2mm |

1361101121 |

| 1.5mm |

1361101151 |

FEATURE / SPEC

■ SUPER GROMMET DESIGN

Although the stock product is not metal, yet the sealing performance is limited due to the grommet type design.

The sealing performance has been improved considerably with the super grommet,to suit these engines and has been proven to brliver excellent relibility.

|

SUPER GROMMET TYPE

The dual sealing method of the bead structure & metal grommet, provides maximum sealing for the coolant, oil & gases around the bore circumference. |

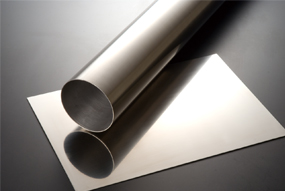

■ Durable stainless steel made

The bead top pry is made of durable but flexible SUS301.

High heat radiation character of SUS301 helps transferring heat of the head and the block to coolant efficiently and prevents heat spots which causes gasket blow.

SUS301 is also known for its tensile strength and it helps the beads to keep sealing the head and cylinder which repeat heat expansion and shrink all the time. This structural strength also improves torsional rigidity of the whole engine by improving coupling rigidity of the head and the block.

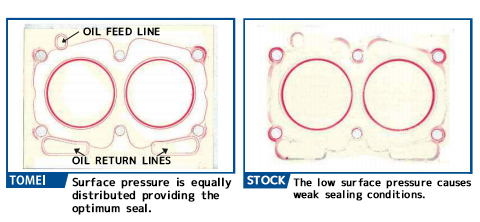

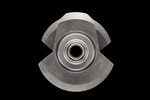

■ APPLICATION SPECIFIC RIB DESIGNS

|

The gas sealing characteristics will improve with the raised rib, but the sealing characteristics of the neighbouring water and oil channels are equally reduced.

Therefore when pushing for power gains, these areas are weak points that can allow leakages.The TOMEI design focuses on all areas to provide the maximum seal with the use of the super grommet design. By using the rib height to ensure an equal overall high surface pressure seal, where it is needed the most. |

■ ABOUT MARKING

All our metal head gaskets are laser marked with Models, Bores, Thickness, and TOMEI POWERED INC. company name.

Since there are similar/counterfeit goods on market, please make sure logos on Gasket. |

|

by Hanshin-Imports | Sep 19, 2018

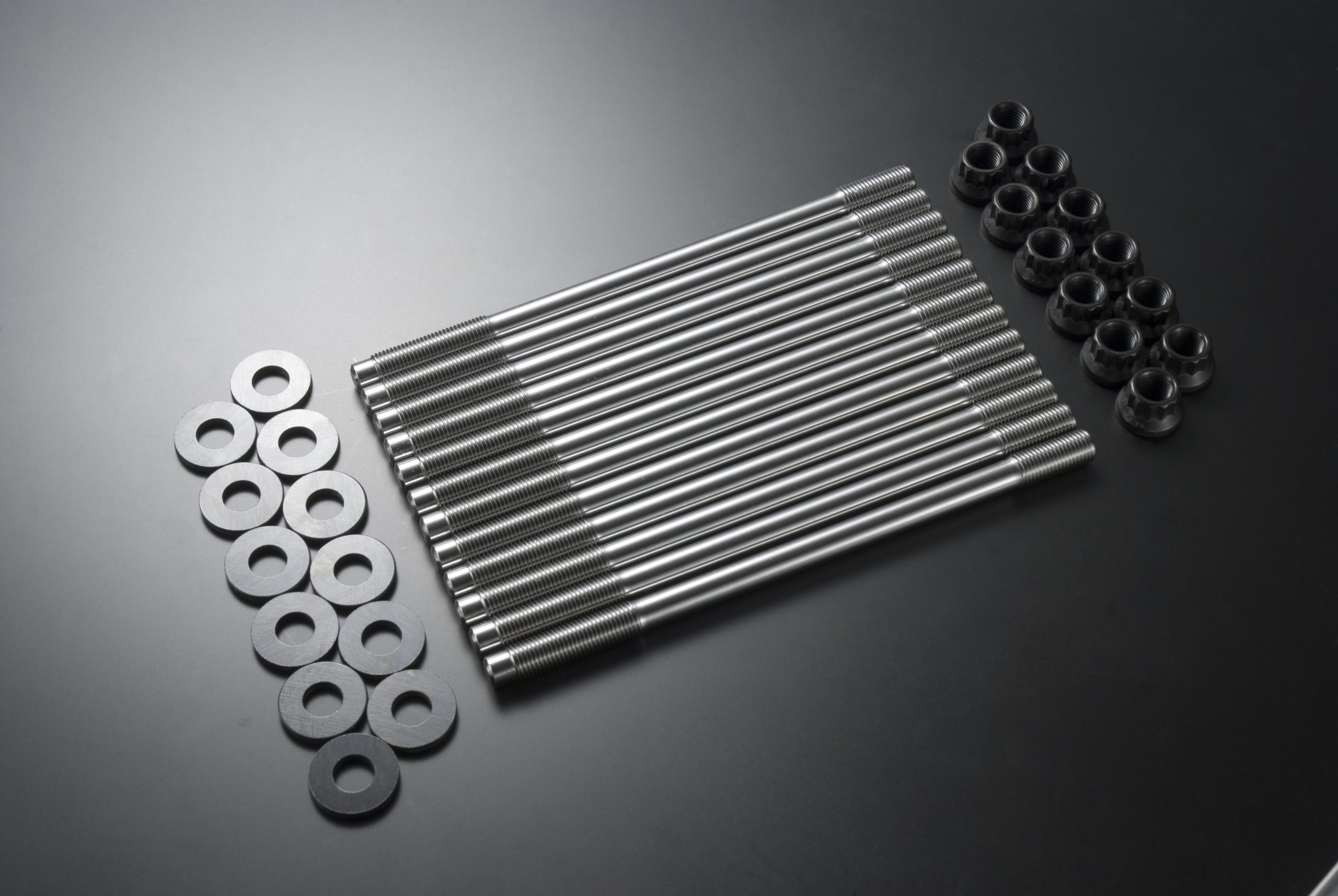

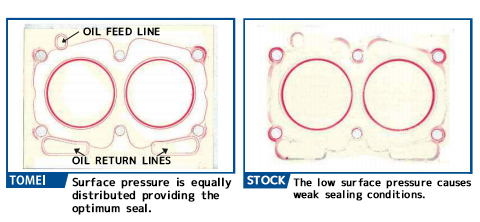

HEAD STUDS EJ20#/EJ25#

REINFORCED BOLT

In order to secure the performance required of head gaskets, such as cooling, rigidity, and sealing, it is necessary to strengthen combination of a cylinder head and a cylinder block. However, in combination with a common bolt and nut, no matter what strengthen bolt it may used, bolting power concentrates on from third mountains to the 1st mountain of the screw, and the total bolting power cannot be increased beyond a certain value. Moreover, excessive stress is concentrated and may damage the bolt. Stud bolt, on the other hand, is applied dynamic design to its threading so that the bolting force is dispersed to all the screw threads and mighty bolting power is generated.

PRODUCT INFO

| APPLICATION |

P/N |

CHF |

CONTENTS |

EJ20#

EJ25# |

193112 |

468.-(Tax inc 504.-) |

・Bolt×12

・Nut×12

・Washer×12 |

* Dummy head cylinder boring is highly recommended to get the best result for the stud bolt installation.

FEATURE / SPEC

| MATERIAL |

* Chromemoly 8740 |

| SIZE |

M10 P1.25 |

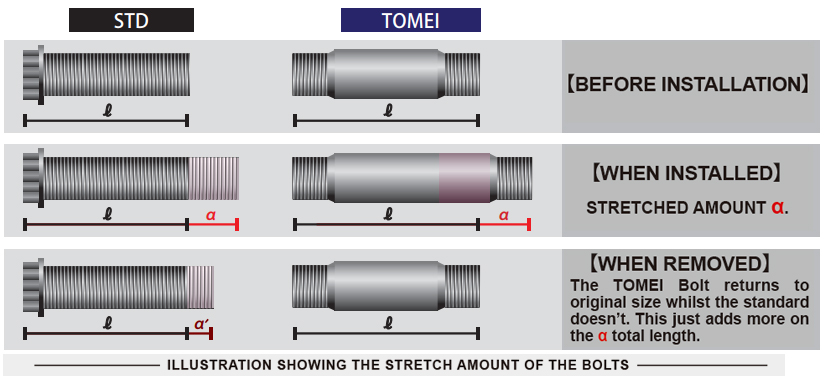

●BOLT STRETCH LIMITS

Bolts and screws in general will stretch when placed under stressful conditions. The stock bolts will tend not to return perfectly to its original shape once stretched due to the manufacturing methods used for the original purpose of the bolt design. Tuned engines will go through many procedures which require the bolts to be reused during every step. When having a dummy head installed and getting a bore and hone, when checking for bearing clearances and so on. So when the bolts are removed and torque up repeatedly bolt stretch management will then become difficult to manage the and retain the strict clearances required. The TOMEI Stud bolts are the best choice for high performance precision engines which require the fixed elastic range of the bolt set for repeated use and to maintain performance. The TOMEI Bolts will keep your engine together when needed most.

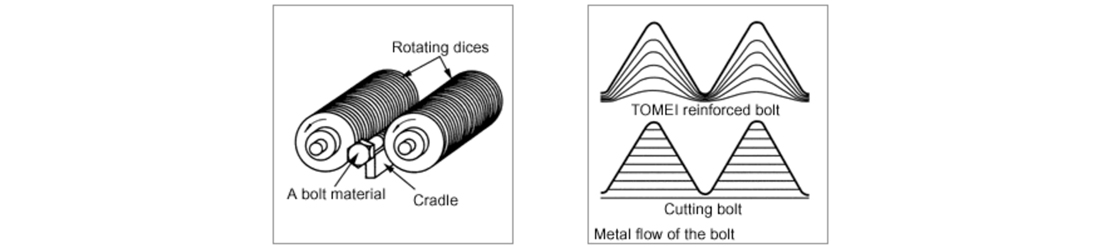

●ROTATING SURFACE HEAT TREATMENT

Rotation processing is the method of Rotating Die and Work Hardening the raw core of the bolt is placed on the cradle between the two rotating die with pressure applied from both sides. The metallic crystals within the bolts are then deformed at a microscopic scale, and then interacted with one another to make up a strengthened bolt that carries increased yield strength. The chromoly steel of the Tomei strengthened bolt is first heat treated and rolled on the rotating die, increasing impact resistance, surface strength, and longevity. These standards add up for the highest quality product available.

●ANGLE TORQUE BOLT TIGHTENING METHOD

An engine cannot be properly built without the use of the angle torque method when tightening certain bolts. It is necessary to utilize a special angle gauge when tightening strengthened studs and connecting rod bolts. Applying torque to the bolts without this specialized tool can lead to immediate or eventual catastrophic failure of the engine assembly.

|

Lack of bolting force |

Excessive bolting force |

| Head bolt |

・Leaking gas, water, oil caused by lack of the sealing pressure

・The further fall of bolting force, loosening, and engine breakage. |

・ Leaking gas, water, and oil from excessive bolting or failure of sealing pressure.

・Breakage of the cylinder from distortion.

・Poor piston clearance caused by cylinder distortion. |

Crank bearing cap bolt

Conrod bearing cap bolt |

・Worn out of the engine by bad bearing assembly.

・Noise by too much clearance of bearing.

・The further fall of bolting force, loosening, and engine breakage. |

・Worn out of the engine by bad bearing assembly.

・Worn out of the engine by poor clearance of the bearing. |

●TORQUE NUMBERS CANNOT BE TRUSTED

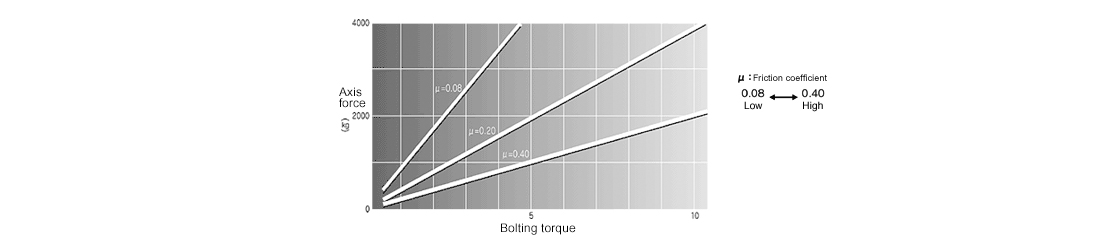

Engine components that require precision accuracy when tightening its bolts cannot be trusted with basic torque figures. This is due to 80~90% of the friction is lost on the surface of the thread and the seat when tightened, with the correct figure being at 10~20% of the torque applied. The surface of the thread and the seat depends on the roughness of each surface and the lubrication state, so that no matter how accurate the torque specs are specified it cannot be trusted.

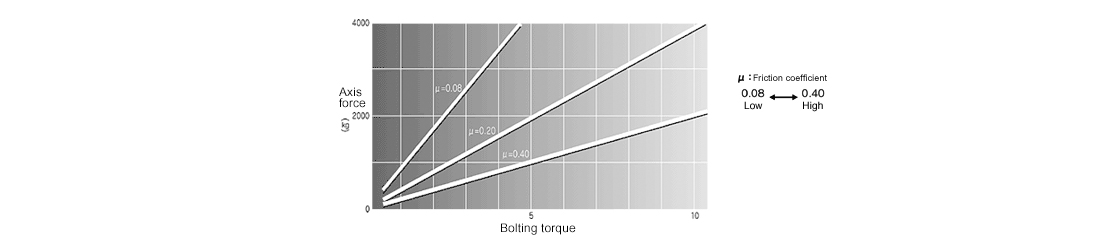

【Change of Axis force due to the difference of friction of the washer】

Please use an Angle Guage as well when torquing up these TOMEI Reinforced Bolts.

by Hanshin-Imports | Sep 19, 2018

|

ENGINE

|

|

APPLICATION

|

|

GRADE

|

SIZE

|

GRADE

COLOR

|

NOTE

OEM

GRADE

|

PART No.

|

PRIX TTC

|

QTY

Required

Per Engine

|

|

SUBARU

|

|

EJ205

EJ207

EJ20Y

EJ255

EJ257

|

GD#

GR#

|

Main1&3

|

Upper/

Lower

Set

|

|

A

|

1.998~2.001

|

Black

|

-

|

126400

|

46.-TTC

|

2 SETS

|

|

B

|

2.001~2.004

|

Green

|

-

|

126401

|

|

C

|

2.004~2.007

|

Yellow

|

-

|

126402

|

|

Main2&4

|

Upper/

Lower

Set

|

|

A

|

1.998~2.001

|

Black

|

-

|

126403

|

41.-TTC

|

2 SETS

|

|

B

|

2.001~2.004

|

Green

|

-

|

126404

|

|

C

|

2.004~2.007

|

Yellow

|

-

|

126405

|

|

Main5

|

Upper/

Lower

Set

|

|

A

|

1.998~2.001

|

Black

|

-

|

126406

|

142.-TTC

|

1 SET

|

|

B

|

2.001~2.004

|

Green

|

-

|

126407

|

|

C

|

2.004~2.007

|

Yellow

|

-

|

126408

|

|

Conrod

|

Upper/

Lower

Set

|

|

A

|

1.485~1.488

|

Black

|

-

|

127400

|

46.-TTC

|

4 SETS

|

|

B

|

1.488~1.491

|

Green

|

-

|

127401

|

|

C

|

1.491~1.494

|

Yellow

|

-

|

127402

|

|

D

|

1.494~1.497

|

Red

|

-

|

127403

|

|

|

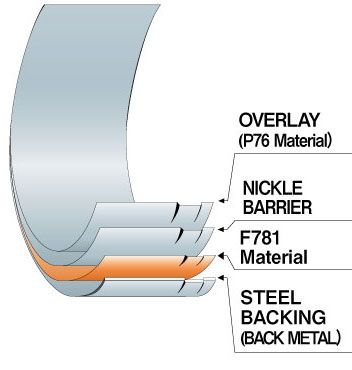

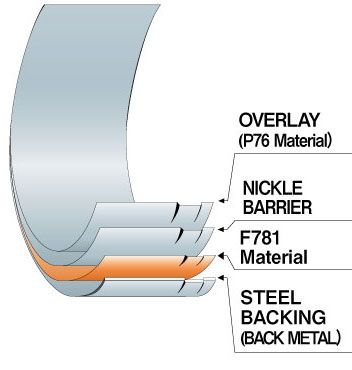

OVERLAY (P76 Material)

The P76 material is used for it’s superior abrasion and fatigue resistance. The elimination of the tin flash plating improves the heat transfer through the bearing.

F781 Material

The F781 material is used on connecting rod bearings for high performance engines. It has a hardened steel backing to improve the support of the bearing lining and assist bearing retention in the housing.

The combination of these material enhancements optimize bearing performance under high loads and temperatures.

|

|

| |

|

|

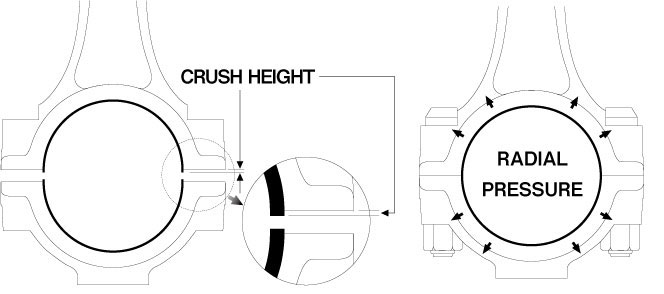

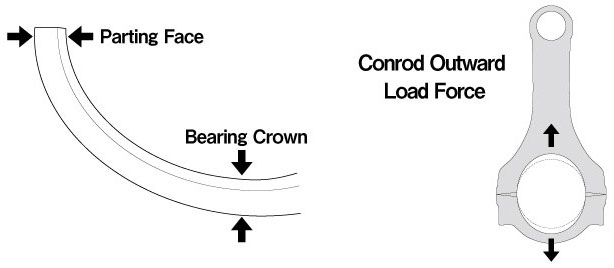

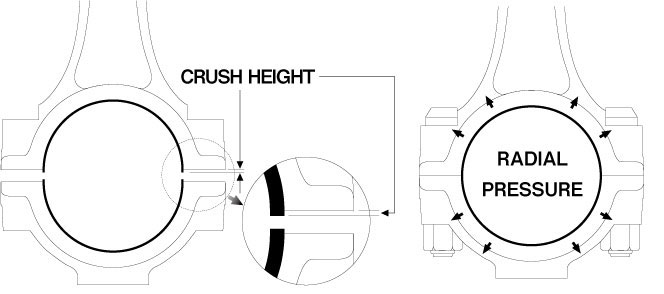

The Competition Bearing Series are designed with an increased crush (i.e. extra bearing length of typically 0.100-0.175mm). The extra crush improves the retention of the bearing in it’s housing.

Crush Height: The crush height is based on the bearing being a fraction longer than the housing seating so that a small section protrudes above the rod bore parting surface. When the rod halves are drawn together, the inserts touch before the halves, thus forcing the inserts tightly into place. |

|

| |

|

|

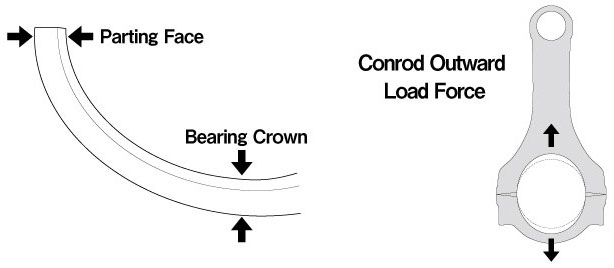

The wall thickness at the crown of the shell is thicker than the wall at 3/8″ down from the parting face. These Competition Bearing Series have an increased amount of eccentricity to compensate for the bearing housing bore elongation in extreme conditions and to help create an effective hydrodynamic oil film.

|

|

| |

|

|

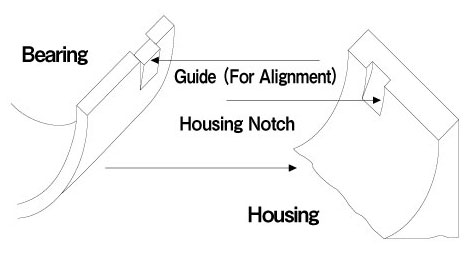

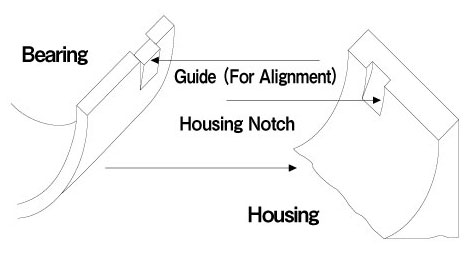

These Notches help with bearing alignment during fitment. They do not hold the bearings in place during operation, that is the function of “Crush”.

|

|

| |

|

|

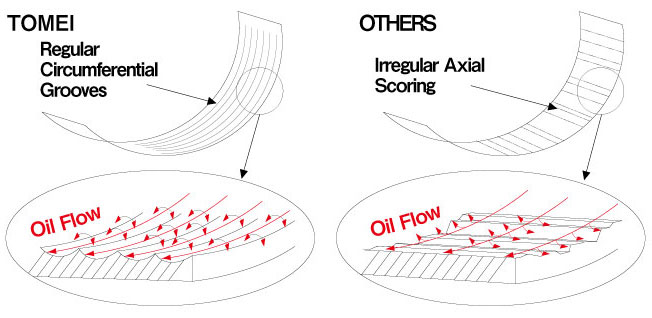

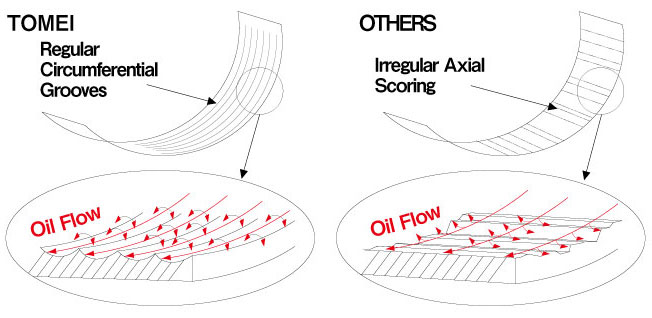

The bore bearing surface finish method helps promote effective oil flow and to maintain adequate lubrication for both the bearings and other moving parts.

|

|

| |

|

|

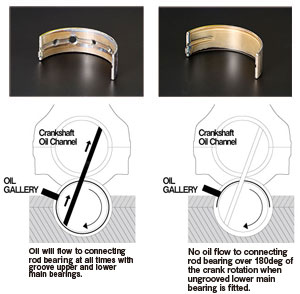

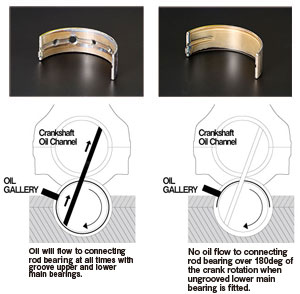

The design of the oil grooves on the lower main bearing shell is always a trade off between oil supply to the Conrods and the bearings load carrying capacity. These TOMEI Competition Bearings generally have a 3/4 groove to give optimum balance of oil flow whilst keeping optimum load carrying capacity.

|

|

by Hanshin-Imports | Sep 19, 2018

|

EJ22 FORGED STRENGTHENED FULLCOUNTER CRANKSHAFT |

|

|

|

|

|

Product

|

Model

|

Part No.

|

CHF

|

Note

|

|

EJ22 Forged Strengthened

Fullcounter Crankshaft

|

2.2L

|

121033

|

1810.-

|

|

|

|

*Stroke:79.0mm (Normal 75.0mm)

*Weight :9.4kg (Normal 9.4kg)

|

| |

|

NITRIDE SURFACE TREATMENT

|

- Minimal Heat Treatment Distortion

- Minimal Size Change

- No reduction in the Cores strength

- Resistance to abrasions & burn characteristics

|

->

|

- Metal protection

- Suited for high output compatibility

- Suited for high revolution

- Improvement Durability

|

|

* Since the metals width is quite narrow for the EJ20 (16.5mm), it is difficult to guarantee the metals strength. So to avoid engine trouble from metal burns we had to increase the surface hardness by using the palsonite hardening process. The end result was an improved metal characteristic that reaches an acceptable level.

|

|

by Hanshin-Imports | Sep 10, 2018

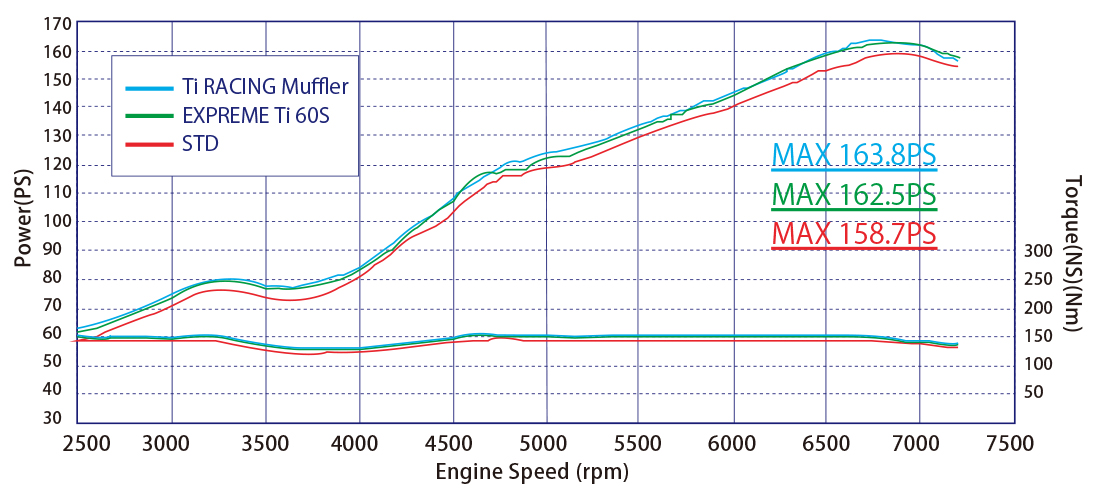

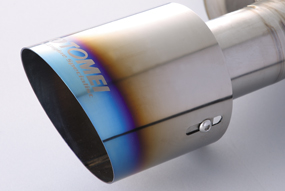

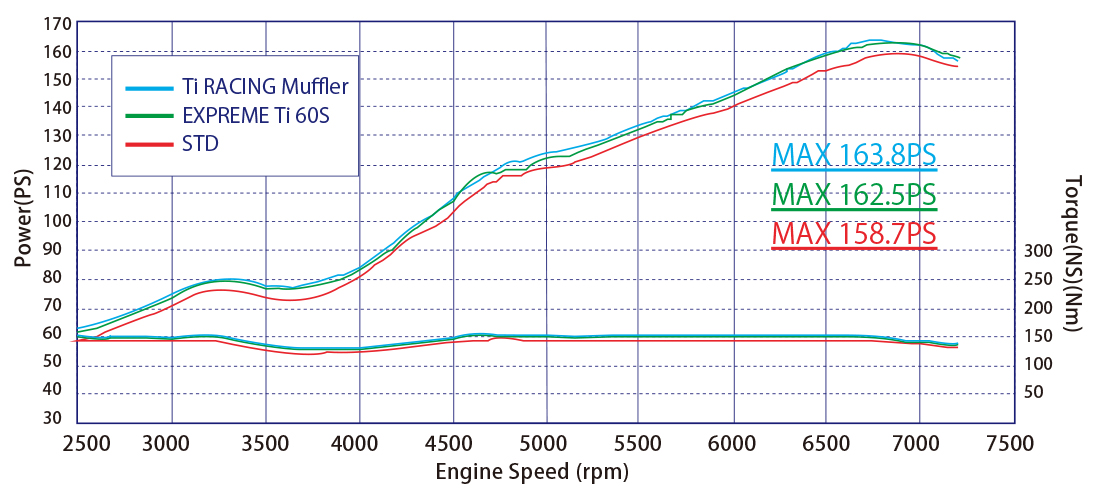

Dual titanium exhaust! High performance, light weight with tuned sound.

This all new Ti RACING 86/BRZ/FR-S exhaust system has been designed to improve the performance at all RPM range from low to mid, and then smoothly shift to high RPM range reducing the well-known the mid range hesitation.

Sub muffler in the main pipe, then split into 2 after axle and 2 mufflers in both side.

This structure helps reducing the sound while maximizing the performance.

Front spherical flange fits the stock front pipe and any other aftermarket front pipe with the spherical style flange.

PRODUCT INFO

| APPLICATION |

P/N |

JPY |

NOTES |

GT86

BRZ

FRS |

441001 |

2199CHF |

※FOR OFF ROAD USE ONLY. |

FEATURE / SPEC

|

|

|

|

|

|

ORIGINAL TITANIUM MATERIAL

To ensure and maintain reasonable price, supreme quality and stable supply, this product is made from TOMEI original titanium material which is refined from raw material and made into performance parts all under quality controlled environment. |

|

END TIPS

Blue burnt titanium color and laser marked TOMEI logo on the end tips.These together give it the great appearance and prove the best quality. |

|

PRECISION WELDS

Titanium is known as a difficult material to weld.Its strength, long-life and beautiful appearance all prove the true quality. |

|

|

|

|

|

|

MAIN MUFFLERS

Large muffler shells eliminates problem of sound issues at the tracks without reducing performance.Stamped TOMEI logo and gradation titanium color on the mirror finished mufflers. |

|

HIGH QUALITY GLASS WOOL

Filled with even more glass wool comparing to existing EXPREME Ti series to reduce and tune the sound.High quality long filament glass wool is very durable and prevents aging deteriorations caused by continues high heat and high pressure. |

|

MAIN PIPE

Same free flow design as the existing models with all new pipe layout to ensure enough ground clearance. |

KIT CONTENTS

|

- MAIN PIPE A (1)

- MAIN PIPE B (1)

- MAIN PIPE C (1)

- MAIN SILENCER LH (1)

- MAIN SILENCER RH (1)

- END TIP (2)

- SILENCER BAND LH (1)

- SILENCER BAND RH (1)

- SPRING (7)

- CLAMP BAND (2)

- FLANGE NUT A M8 (2)

- FLANGE BOLT M8 L=22 (2)

- FLANGE NUT B M8 (2)

- FLANGE BOLT M8 L=55(2)

- BAND RUBBER (2)

- BUTTON BOLT (4)

- BOLT SMOOTH PASTE(1)

- ALLEN KEY (1)

|

This all new design meets and exceeds the performance of existing EXPREME Ti series which is full-straight structure. This full titanium dual exhaust system also lowers 7.5kg in the total weight comparing to the stock exhaust..

*This exhaust system may be louder with late model.

|

Ti RACING |

TYPE-60S |

STD |

| MATERIAL |

TITANIUM |

TITANIUM |

STEEL |

| MAIN PIPE DIAMETER |

Φ60.5 |

Φ60.5 |

Φ54.0 |

| SUB SILENCER DIAMETER |

Φ120 |

Φ115 |

Φ100 |

| MAIN SILENCER DIAMETER |

Φ152 |

Φ115 |

Φ350x 190 OVAL |

| PIPE THICKNESS |

1mm |

1mm |

1.2mm |

| EXIT DIAMETER |

Φ102 |

Φ105 |

Φ90×75 |

| EXIT STYLE |

SLANT CUT / DUAL OUT |

– |

OVAL DOUBLE PIPE / DUAL OUT |

| FLANGE THICKNESS |

2.0mm |

2.0mm |

2.0mm |

| EXHAUST TEST LEVELS |

前期MT |

後期MT |

IDLING:66.0db

5260RPM:95.0db

IDLING(With Inner Silencer):65.0db

5260RPM(With Inner Silencer):92.0db

*measured in early model with M/T. |

IDLING:59.5db

5260RPM:88.5db

*measured in early model with M/T. |

IDLING:63.5db

5260RPM:91.0db |

IDLING:69.5db

5260RPM:97.0db |

| WEIGHT |

9.85kg |

6.4kg |

17.4kg |