Fujitsubo

FUJITSUBO Technology

Fujitsubo’s spirit is to “produce the highest quality products”. This has not changed since Fujitsubo was first established in 1931. This spirit does not only pertain to creating highly efficient and high quality exhausts and manifolds, but it also applies to our customer’s satisfaction. This is the reason Research and development is performed with people, motor vehicles, society, environment etc, all thought as one, to create a product through diversity.

Fujitsubo is continuously pursuing advanced technologies. A chassis dynometer, 1/3 octave band sound analysis device, and other specialized equipment are utilized to accumulate important data from the latest technologies. Increased productivity through advanced 3D laser processing machines and automated pipe benders. Strict quality control with CCD cameras, image analysis software, and 3D CAD. Cumulative performance analysis through actual vehicle testing. This type of research, development, and production structure has led to the Fujitsubo patented exhaust manifold (Pat. No. 1320379).

Detail

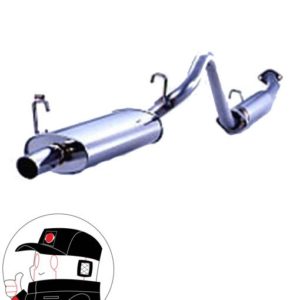

Muffler

The specifications for the Muffler(canister and resonator) are tested for each vehicle to obtain optimal efficiency and noise reduction. Utilization of Punching pipe, stainless demister, glass wool, cut wool etc are aid in noise reduction. Combined with unique sound tuning and improvement in exhaust efficiency, a sporty exhaust sound is achieved.

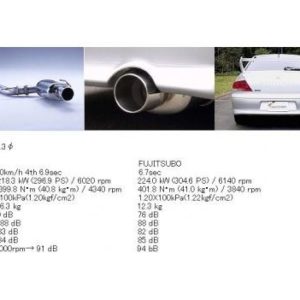

Straight Construction

DPS(Dual Pipe System) Construction

Reactive Construction

- Lightweight Press Mold Flange

- A lightweight press mould flange has been implemented in the product dissection department to research lightweight technology. Intense strength of t=2.3mm has been achieved (some products not included).

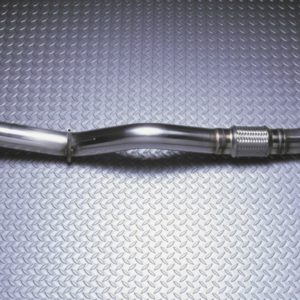

- Donut type Joint

- Stress on the exhaust system has been successfully decreased through high quality flex joints. Vibration from engine and chassis are absorbed by the flex joint reducing stress to the exhaust system.

- Lightweight Hollow Pipe Hanger

- Use of Lightweight hollow pipe hangers allows for more than 50% weight reduction and at the same time, is more efficient in preventing the support rubber from detaching, when compared to a solid equivalent.

- Thin Hanger Baseplate

- Concentration of stress is prevented through the base plate.

- SUS304 Stainless Welded Parts

- TIG welding is used exclusively for a combination of strength and durability, as well as a high quality finish.

- Straight Layout

- Through research is performed on each application to find the most efficient and free flowing path for the exhaust from the main pipe to the exhaust tip.

- Racing Experience

- Fujitsubo continues to challenge. The Fujitsubo Impreza takes part in the Super Taikyu endurance racing series. Valuable experience is acquired in a variety of motorsports activities. This assists in new product development and drives development of new innovative technologies, meeting the needs change, which is thought as a valuable asset.

Hanshin-Imports Sàrl is proud to announce its partnership with Fujitsubo as its official Distributor in Switzerland!

Fujitsubo Switzerland (Hanshin-Imports) first local partner in Europe for Fujitsubo Giken Kogyo Co., Ltd.

Showing 1–20 of 33 resultsSorted by popularity

-

Fujitsubo Legalis R typeEVOLUTION Toyota Supra JZA80

CHF1,496Available on backorder

-

Fujitsubo Legalis R S-Tail Toyota Corolla AE86 Single

CHF1,290Available on backorder

-

Fujitsubo Catback Legalis R Toyota Chaser Cresta Mark 2 JZX100

CHF1,164Available on backorder

-

Fujitsubo Legalis R Mitsubishi Lancer EVO 7-9

CHF1,154Available on backorder

-

Fujitsubo RM-01A for Mitsubishi Lancer EVO 4-5-6

Price range: CHF1,104 through CHF1,255Available on backorder

-

Fujitsubo Power Getter Mazda Mx5 NA6CE 1.6 & NA8CE 1.8

CHF1,5261 in stock (can be backordered)

-

Fujitsubo Authorize A-R Suzuki Swift Sport 2019

CHF1,601Available on backorder

-

Fujitsubo Legalis R W-Tail Toyota Corolla AE86 Twin

CHF1,285Available on backorder

-

Fujitsubo LegalisR Honda Civic EK4 and EK3

CHF1,350Available for Backorder (3-6weeks lead time)

-

Fujitsubo Power Getter Honda S2000 Single Exit

CHF1,164Available on backorder

-

Fujitsubo Legalis R Toyota Celica GTFour ST205

CHF1,370Available on backorder

-

Fujitsubo Legalis R Toyota Supra 3.0 Turbo MA70

CHF1,455Available on backorder

-

Fujitsubo RM-01A Honda Integra Type R DC2

CHF1,556Available on backorder

-

Fujitsubo Power Getter Honda Integra Type R DC2

CHF1,782Available on backorder

-

Fujitsubo Front Pipe for Mitsubishi Lancer EVO 4-5-6

CHF501Available on backorder

-

Fujitsubo Legalis Super R Mitsubishi Lancer EVO 4-5-6

CHF1,154Available on backorder

-

Fujitsubo Legalis R Mazda RX-7 FC3S

CHF2,173Available on backorder

-

Fujitsubo Legalis R Toyota Supra JZA80

CHF1,882Available on backorder